| C R G | CRG Reports | Exterior | Engine | 1967 Model ID |

| Numbers Decode | General Info | Interior | Transmission | 1968 Model ID |

| Drivetrain Decode | Options | Underhood | Chassis | 1969 Model ID |

©1998-2025, Camaro Research Group

Edited by Kurt Sonen and Rich Fields

Version: Monday, 16-Feb-2026 23:59:05 EST

All 1967 models used monoleaf design rear springs.

For 1968, only models with the 12-bolt rear end received multi-leaf springs. This included all SS models, the Z28, and the L30/M20 327/275hp 4-speed. All other 1968 models used monoleaf springs.

In 1969, all models with 12-bolt axles received multi-leaf springs and all models with 350ci engines (10- or 12-bolt) received multi-leaf springs. Vehicles with 307 and 327 engines received mono-leaf springs.

All 68-69 Z28's used 4-leaf springs. Generally, the other multi-leaf spring applications used 5-leaf springs. However, the use of 4-leaf springs was not limited to just 68-69 Z28's. Spring selection was a function of weight and options - and this was fine-tuned in 1969. SS, LM1, L65, and COPO cars with 4-leaf springs are possible according to factory documentation and they have been observed on original SS, LM1, and L65 cars.

Here are the spring tables for all three years:

In addition, 12-bolt axles were installed on the following cars:

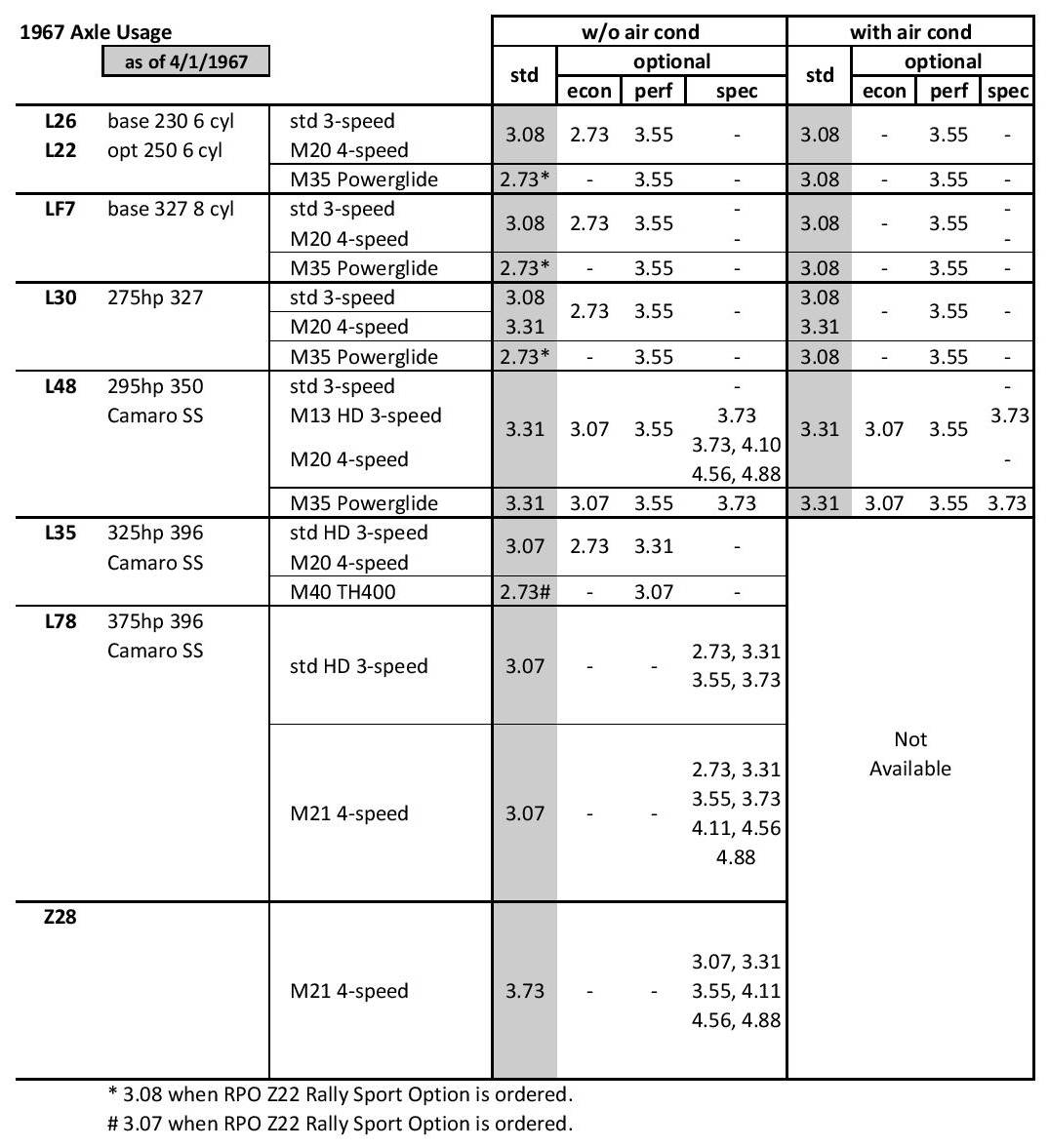

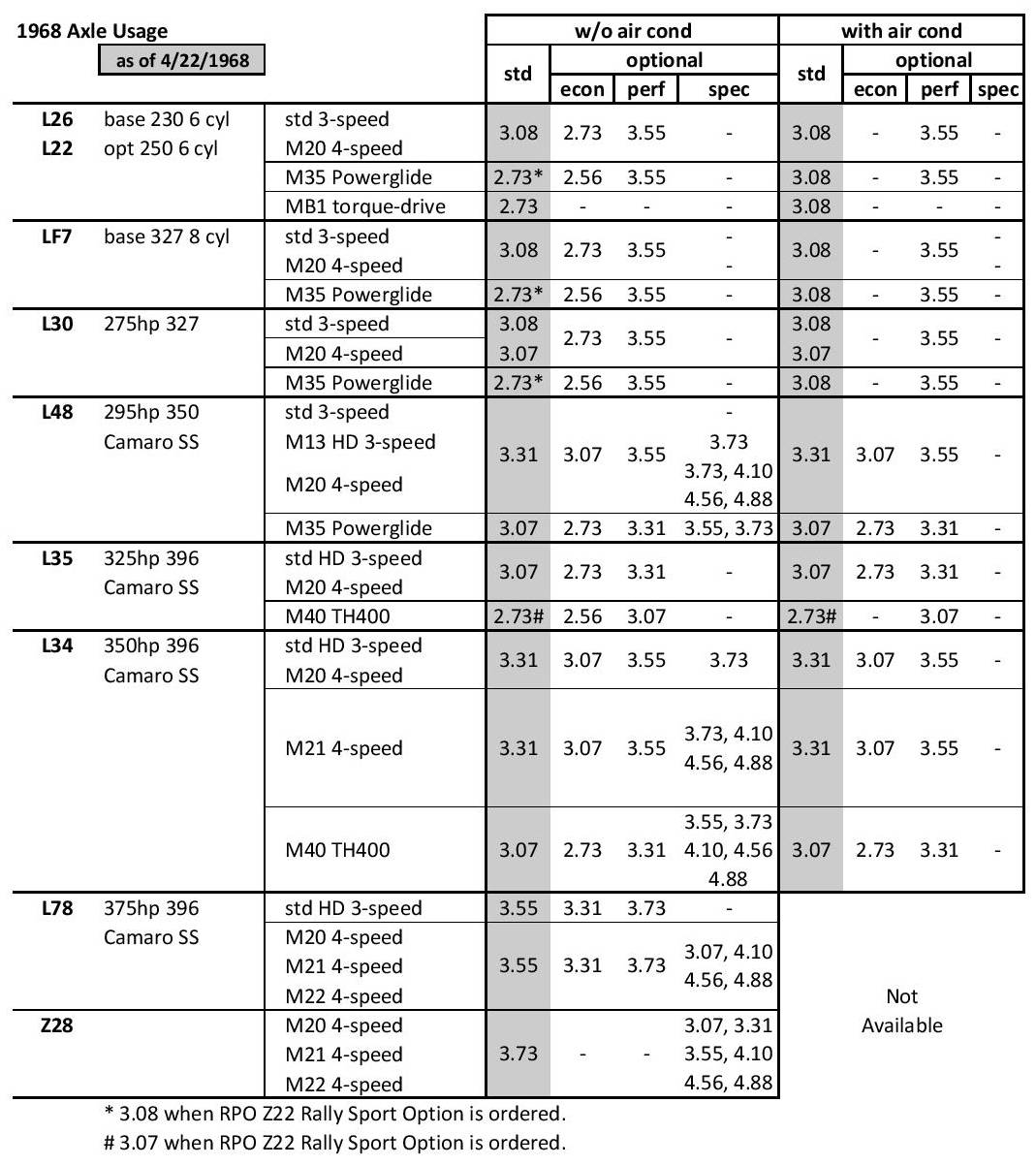

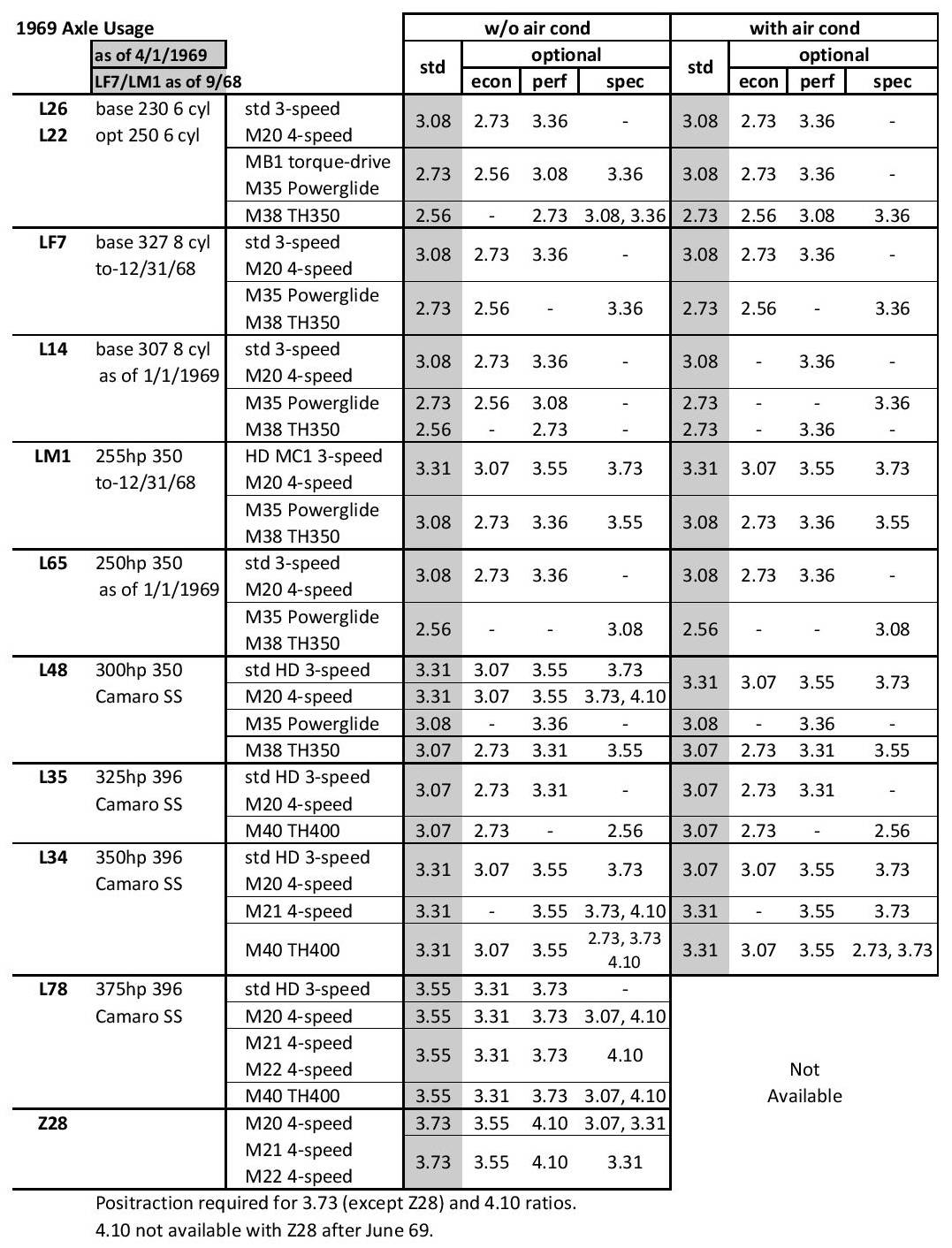

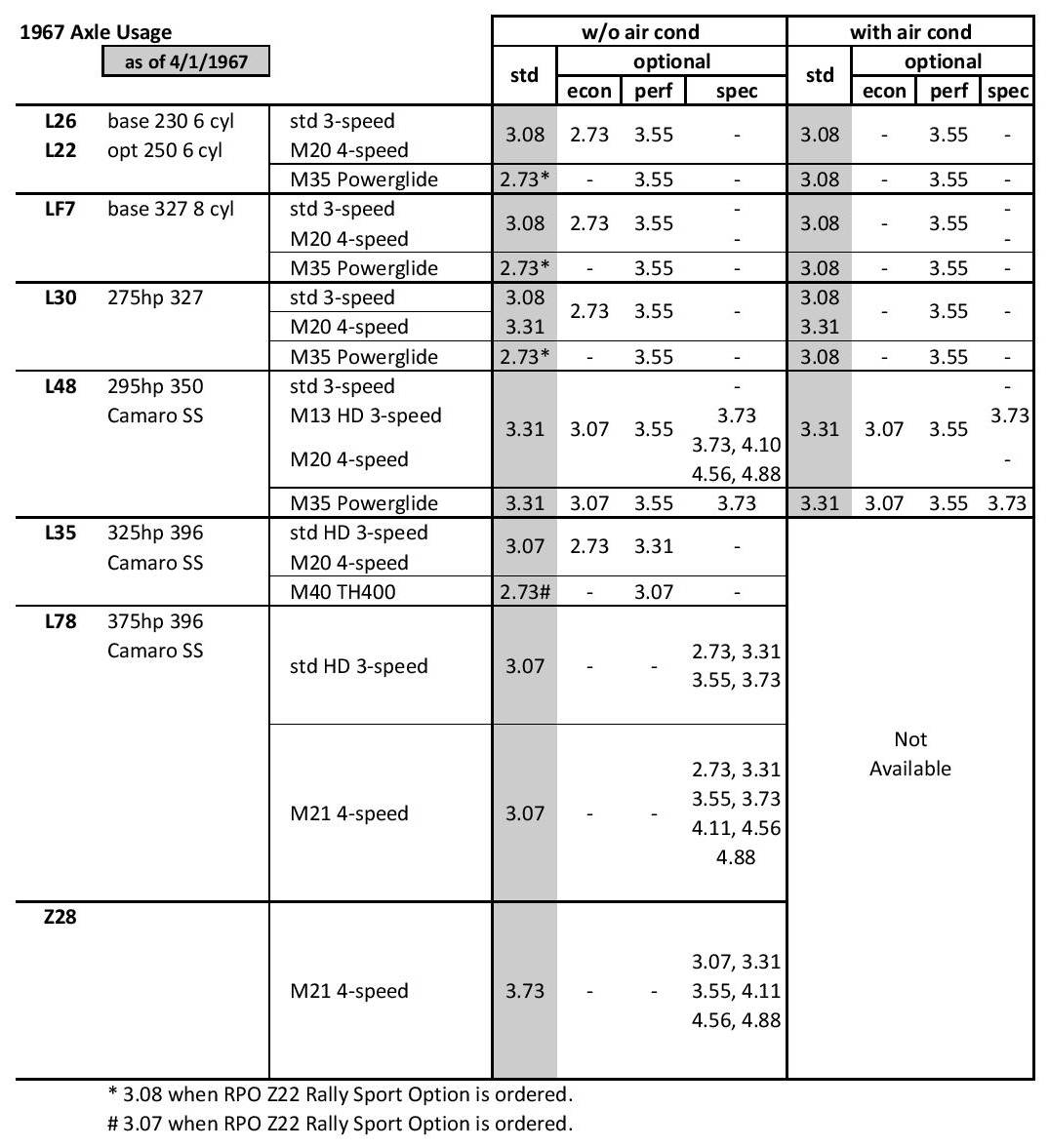

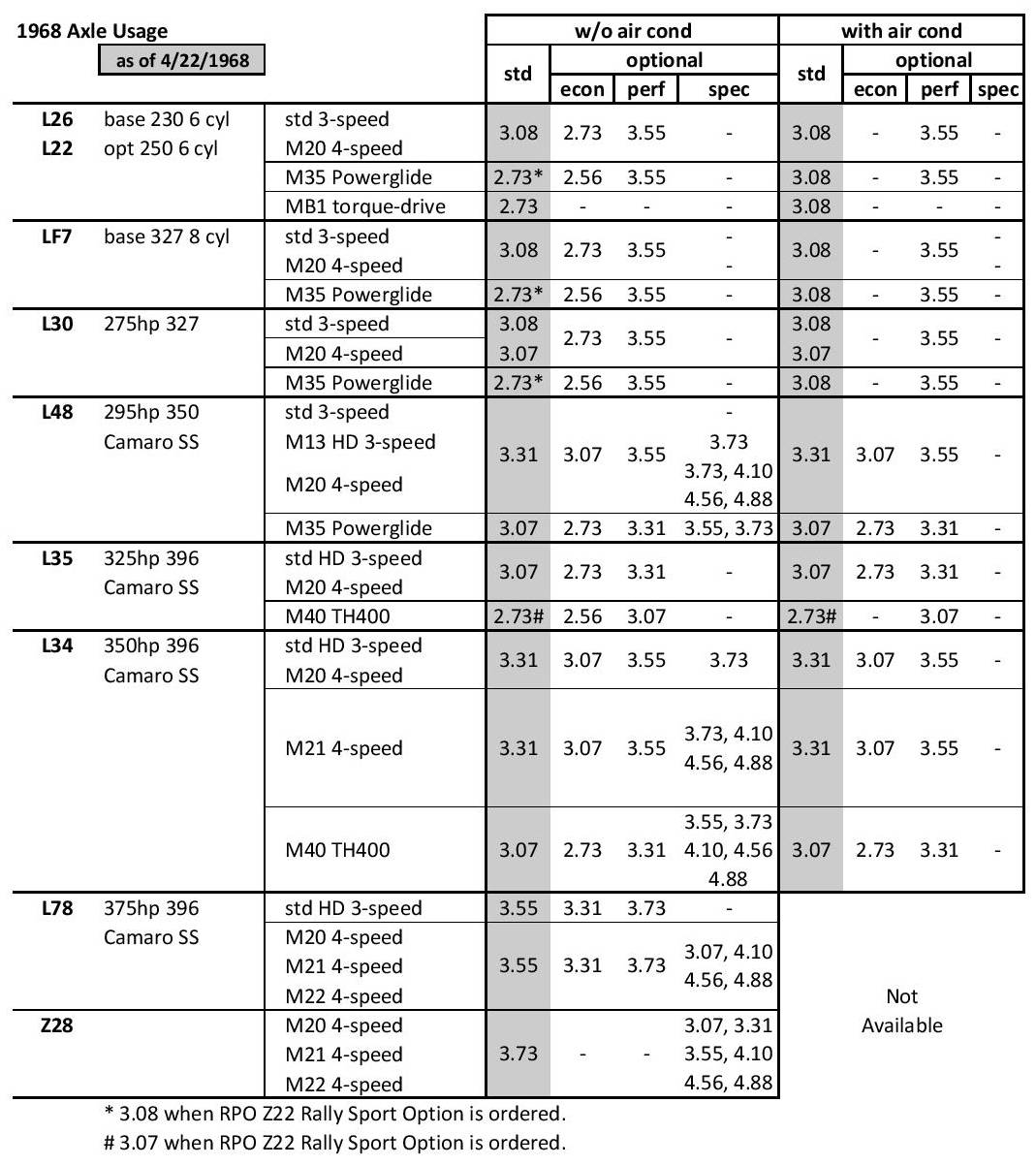

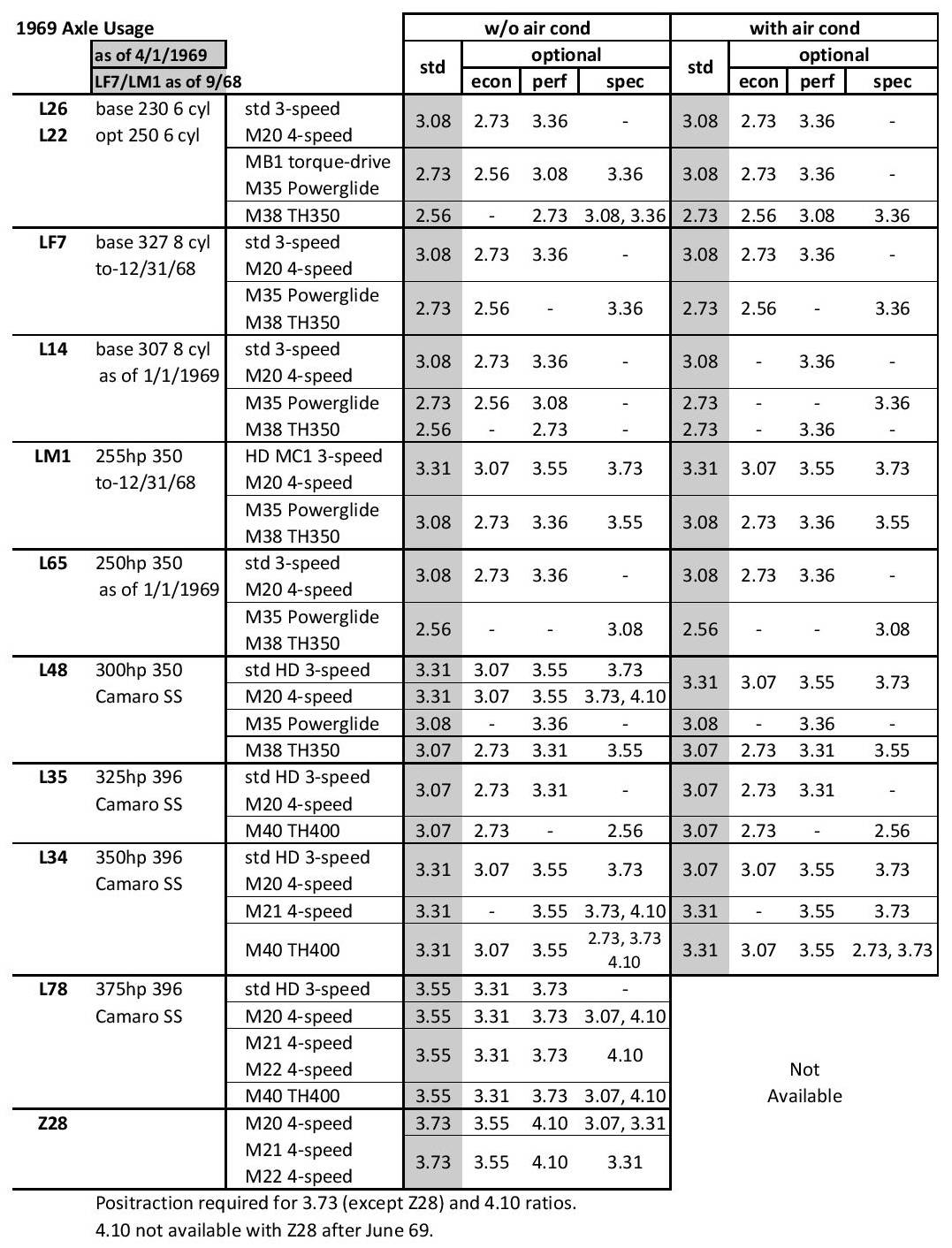

| 1967 Axle Ratios | 1968 Axle Ratios | 1969 Axle Ratios | ||

|

|

|

Lower A-Arms

The lower a-arms used for the 1st-gen Camaros had small but noticeable

differences for all three years. This was primarily due to changes in

the location of the rubber bump stop which was used to cushion

any contact with the frame upon full compression of the suspension.

It is unknown why the location of the rubber bump stop changed each year.

In 67, the rubber bump stop was mounted on a bracket which was welded to the frame, thus there is no rubber piece mounted on the lower a-arm and no holes drilled in the a-arm to do so. For 68, a newly designed larger rubber bump stop was mounted (through two drilled holes) on the trailing side of the a-arm. The mounting bracket for the rubber bump stop (which had been in-line with the centerline of the wheel in 67) was removed and a newly designed metal contact pad for the rubber bump stop was mounted on the trailing side of the coil spring pocket on the frame. For 69, the same rubber bump stop was moved to the leading edge of the lower a-arm and the corresponding metal contact pad on the frame followed suit to the leading side of the coil spring pocket. All service replacement a-arms included mounting holes for both the 68 and 69 positioning of the rubber bump stop. Obviously, these holes are not relevant for the 67 application since the rubber piece is on the frame.

The 67 and 68 lower a-arms use welded-in nuts for the lower shock mount. For 69 and for all service replacement a-arms, the shock mounting nuts were attached by a J-clip, which simplified the nut installation and also allowed for easy replacement.

The Assembly Instruction Manuals for all three years show different part numbers for the lower a-arm assembly for drum brakes and the lower a-arm assembly for disc brakes. Despite analysis of the parts, the difference is unknown; it may involve another component of the a-arm assembly.

1967 included two one-year-only brake options:

- The RPO J65 metallic drum brake option added metallic brake shoes on all 4 drums.

J65 was supposedly only available on 67 SS's but it has been observed

on a few non-SS cars.

- The RPO J56 heavy

duty disc brake option was only available on 67 Z28's and was

in addition to the required J50 and J52 options. It consisted

of heat insulators on the disc brake caliper pistons and

metallic rear drum linings. Both RPO J65 and J56 used

the same metallic rear drum linings (and thus used the same

metallic brake rear axle assemblies).

A modified version of the OTC system was released in 1969 for production as RPO JL8, 4-Wheel Power Disc Brakes. The option was only produced during a limited timeframe, from Feb 69 to May 69, and production was only 206 units. The JL8 option was available on any Camaro model; the cost was $500.30 for SS or Z28 models and $623.50 for non-SS non-Z28 models. All JL8 cars received the 15x7 rally wheels. Most JL8's were installed on Z28's, but GM documentation indicates that 27 non-Z28's had JL8. Both SS and non-Z28 non-SS Camaros have been verified as receiving JL8!

Many of the disc-brake rear axles that survive are the HD service units, rather than JL8. There are easily identifiable physical differences between the JL8 and the service axles. The most notable is the factory-installed axle tube is tapered at the brake flange mounting plate, while the service axle has a larger diameter tube with no taper. See Wayne Guinn's book, Camaro Untold Secrets 1967-1969, for details on other differences.

Note: Disc brakes required special wheels with a different centerline-to-attach-plane offset. See the wheels information for the relationship between brakes and wheels.

|

|

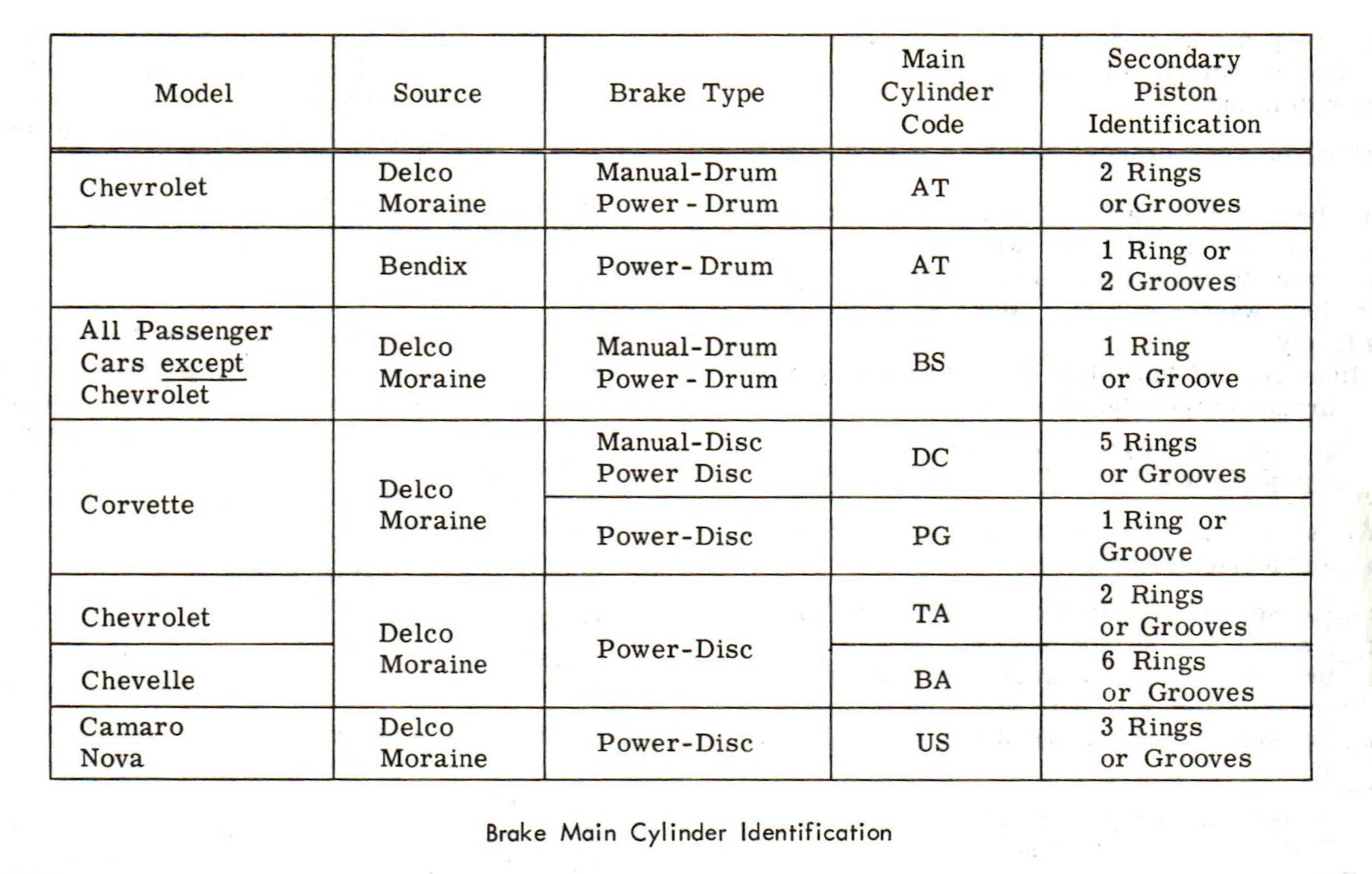

67-69 manual drum brake cars used the 5452310 casting except 1967 cars with manual J65 drum brakes used the 5461862 casting. Power drum brake cars used the 5460465 casting.

1967 manual disc brake cars used the 5459467 master cylinder casting. 1967 and 1968 power disc brake cars used the 5460346 master cylinder. Early 1969 disc brake cars also used the 5460346 master cylinder (for about a month or so of production) with later 69 cars using the 5468309 casting.

Power drum and power disc brake master cylinders were installed at an angle which trapped air in the bores of the master cylinder. Bleeder valves were installed to allow this air to be purged from the system. The manual disc brake master cylinders were installed horizontally and did not have bleeder valves. We believe the manual drum master cylinders also did not have bleeders, but there is some conflicting data and this is still being researched.

The application code for the master cylinder was stamped on a small pad on the front of the casting, as shown in the sketch below. Note the tag with the broadcast code also shown in the sketch. The broadcast code and the master cylinder application code are not the same; the broadcast code is for the entire assembly and the application code is for the bare master cylinder.

1969 J52 disc brake systems and JL8 four wheel disc brake systems used the same master cylinders. The only difference between the master cylinders was the J52 master cylinder had a residual pressure valve (aka check valve) in the outlet for the rear drum brakes, whereas the JL8 master cylinder did not have any check valves.

* GM documentation confirms that drum brake master cylinders are BS code and most drum brake master cylinders are coded BS. But a limited number have been observed with the CT code, in both manual and power drum applications. The CT code was used on drum brake applications on Pontiac and Buick vehicles. It is presumed that the CT part was used as a substitute during a parts shortage that and the differences between the BS and CT master cylinders are minor. The CT code is shown in the applications observed so far.

| Power Disc Brake Master Cylinder | 1967 Manual Disc Brake Master Cylinder | 1969 Master Cylinder Applications | ||

|

|

|

On certain Camaro models, a rear brake pressure regulator valve (aka proportioning valve) was utilized. This valve requires a two-piece rear brake line and mounts on the rear of the front subframe under the driver's door. The valve is also discussed in the Camaro brake valves article.

On the new 1967 Camaro, this valve was initially used only on models with factory C60 air conditioning and it was described in the 1967 Chassis Service Manual in the following way:On Camaro models equipped with air conditioning, the rear brake hydraulic line is routed through a pressure regulator valve mounted on the left frame side rail (fig 3). The valve controls the hydraulic pressure to the rear brakes resulting in the correct pressure balance between the front and rear hydraulic systems.The November 1969 Chevrolet Service News adds the following, complete with a pressure table (note that by 1970, the emphasis in the description was on front disc brakes, though the valve was also used on certain 67-69 drum brake cars):

The valve limits the amount of hydraulic pressure, at a controlled rate, to the rear wheels in proportion to the amount of pressure to the front wheels. ... This action prevents the rear brakes from locking up before the full effective braking effort is produced by the front disc brakes.

The implicit rationalization in the 1967 description was that the valve was needed to improve stopping due to higher front end weight resulting from the C60 air conditioning equipment. Restricting use to C60 is suspect logic; there were other options that added the same (or greater) front end weight. For example, in 1967, an otherwise optionless L6 with C60 would get it, while a RS/SS350 with smog, power brakes, and power steering (but no C60) would not get the valve, despite having a higher front-end weight.

Valve UsageThe manual and power steering gearbox castings used on Camaros were also used for many years on other GM vehicles. The main manual gearbox used on Camaros was casting number 5679142 with 3 mounting ears. An alternate box 5696084 with 4 mounting ears was sometimes used in 1967. The part number is cast on the bottom of 084 box and there is no assembly date stamp on them. The power steering box was casting 5691676. Many different gearsets for many different applications were installed in those castings. There are no permanent markings on the gearbox to identify the original usage of a box. The date will be cast into the side of the box.

|

|

The assembly date on manual boxes is stamped on a pad next to the cover. The

format is a letter (presumed to be the shift), the Julian day

, and the year: (A or B)dddy. For example, A1308 indicates the 130th day of 1968.

On power steering boxes, the assembly date is stamped on the aluminum cover. The

format is the Julian day and the year: ddd y. For example, 343 7 is the 343rd day of 1967.

The pitman arms for manual steering and power steering use the same forging, but the splined holes for the attachment to the steering box are different diameters.

67 and 68 Steering

67

The long pitman arm, 3908391, 5.8" long, was used in the 67 Camaros. The 3908385

idler arm, 5.8" long, was used on 67 Camaros.

68

The 3908391 long pitman arm was used in 68 Z28's. Other 68 Camaros used the

3935075, 5.25" long, pitman arm (both manual and power steering). The idler arm for

68 was 3917581, 5.25" long.

|

|

69 Manual Steering

69 manual steering boxes used an aluminum cover.

Most 69's used the same manual steering gear. Changes to the steering linkage

were used to change the overall steering ratio.

- Regular cars were equipped with a shorter 5.25" pitman arm (forging # 3953219)

and longer steering arms (3954873 RH and 3954874 LH).

- Z28 and RPO N44 (special steering) cars utilized a longer pitman arm (forging

# 3953227, 5.8" center-center) and shorter steering arms (3954875 LH and 3954876 RH).

A special fast-ratio manual steering gear was used for Z28's with RPO N44. The manual Z28 with N44 used with the same longer pitman arm and shorter steering arm combination as listed above - the steering box is different. Z28's with N44 are very uncommon (and not fun to drive).

69 Power Steering

All 69's used the same variable ratio power steering gearbox with approximately

2 1/3 turns lock to lock. Z28, L78, and COPO cars had a

deep groove pulley on the power steering pump.

- Non-Z28 and non-SS cars with power steering used a 5.25" pitman arm (forging #

3953219) and the longer steering arms (3954873 RH and 3954874 LH).

- Z28, SS, and RPO N44 had a faster overall ratio by using a longer 5.8" pitman arm

(forging # 3953227) combined with shorter steering arms (3954875 LH and 3954876 RH).

The 69 idler arm was the same as the 68, 3917581, 5.25" long.

The drag link (a.k.a. center link) for 69 power steering system is 1.125" in diameter, much larger in diameter than the .95" drag link used for manual steering.

Most wheels are dated as shown below in the table. K18 5 25 XG would decode as a 14x6 rally wheel for disc brakes made by Kelsey-Hayes on 5/25/68. 67 and 68 FC coded wheels are often stamped with an alternate date format: ddmmy (day, month, year), stamped on the rim lip but not next to the valve stem.

|

|

Wheels were painted black if full disc style hubcaps were ordered on the car. If the smaller 'dogdish' style hubcaps were installed, the wheels were painted body color. Rally wheels were painted 'argent silver'. All wheels were painted with enamel paint.

For 1967, rally wheels were required when disc brakes were ordered. This restriction was removed in 1968 (despite some 1968 dealer literature that indicates that disc brakes were required with rally wheels). Which means that in 1968-69, disc brake cars came with plain steel wheels, unless the ZJ7 rally wheel option was added (except for Z28 which included rally wheels).

While a promotional photo exists of a 69 Z28 with the narrower 68 15x6 DF wheels, this wheel was not used on 1969 Z28's in production. The initial 69 Z28 wheel was coded AD. The YH wheel was produced starting mid-December 68 and had minor modifications to increase clearance for the JL8 brake components.

Year Type Brakes Code Size Application

---- ----- ------ ---- ---- -----------

1967 Steel Drum B 14x5 Base

Steel Drum FC 14x6 Base (opt), SS

Rally Disc DA 14x5 Base

Rally Disc DG 14x6 Base (opt), SS

Rally Disc DF 15x6 Z28

1968 Steel Drum FC 14x6 Base, SS

Steel Disc XF 14x6 Base, SS

Rally Drum XN 14x6 Base, SS

Rally Disc XG 14x6 Base, SS

Rally Disc DF 15x6 Z28

1969 Steel Drum FC 14x6 Base

Steel Disc XF 14x6 Base

Steel Disc XT 14x7 SS, COPO

Steel Disc IF 14x7 SS (observed on early LOS cars)

Rally Drum XN 14x6 Base

Rally Disc XG 14x6 Base

Rally Disc YJ 14x7 SS

Rally Disc AD 15x7 Z28 (early)

Rally Disc YH 15x7 Z28 (late)

"SS" Disc YA 14x7 SS RPO N66 *

*cancelled in documentation 1/8/69

|

|

|