CRG Research Report

1967 Camaro Metallic Brakes

© 2013-2019,

Camaro Research Group

Primary Author -

Reviewed by the CRG

Last Edit: 20-Mar-2017

Previous Edit: 05-Feb-2013

Original Release: 05-Feb-2013

|

Index

-

RPO J56 (disc/drum)

-

RPO J65 (drum/drum)

-

Master Cylinders and Brake Valve Usage

-

Replacement Brake Shoes

-

Summary/Acknowledgements

Introduction

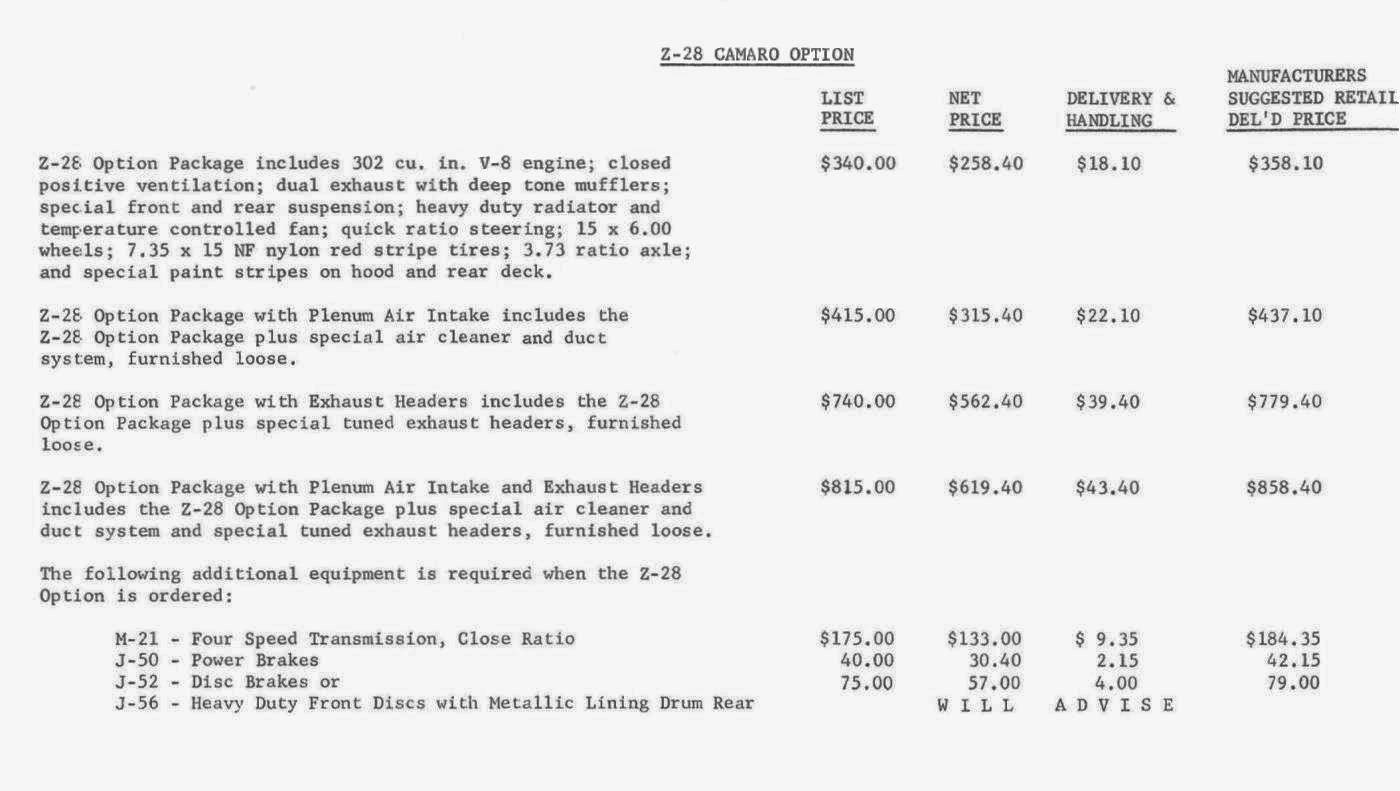

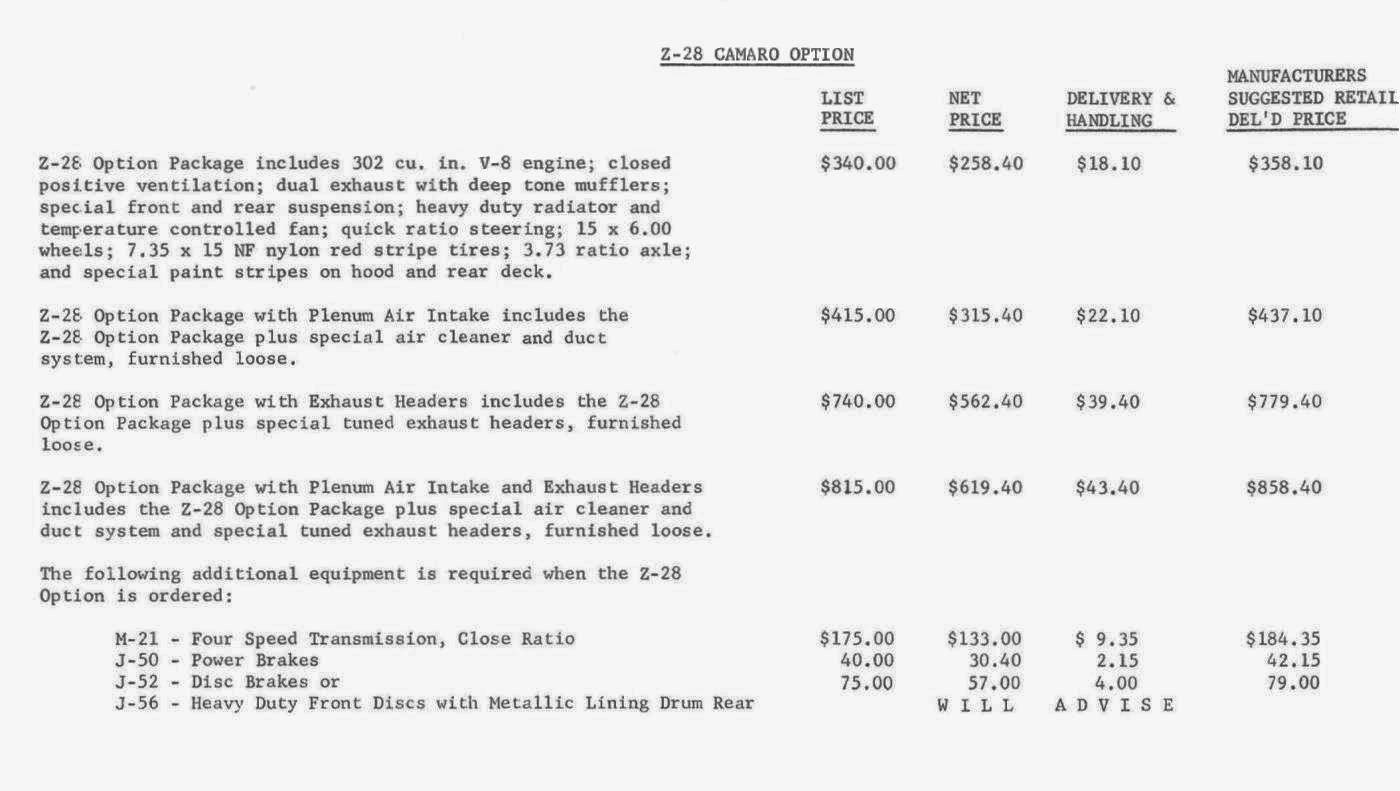

1967 Camaro Brake RPOs

RPO Description Cost Qty sold

----- -------------------------------- -------- --------

J50 Power brakes $42.15 24,549

J52 Brakes, Front disc $79.00 14,899

J56 Brakes, HD front disc with

metallic-faced drum rear

(J50 & J52 mandatory with J56) $26.35 205

J65 Brakes, special metallic

facing (front and rear) $36.90 1,217

|

This article has been written to shed light on two special brake packages

that, up until now, have been largely ignored. Very little written detail

was found while researching the subject, even in original GM literature and

documentation. It seemed odd that the topic of the 4-wheel disc package in '68

and '69 was well covered and had an avid group of followers, yet the

earlier special brake packages were pretty much absent from all conversation.

Personally, this seemed a bit like opening a book and starting at

Chapter 3. My personal frustration set me off on a quest - a quest to satisfy

my thirst for knowledge for two brake packages that are both extremely rare

and limited to the first year of production; the year 1967.

This article describes the original components and applications for the 1967

Camaro metallic brake options, identified by the factory Regular Production

Option (RPO) codes of J56 and J65.

RPO J56 was a heavy-duty brake option for the Camaro available only on the

'67 Z28. Like the RPO J52 disc brake package (an available option

on any Camaro model), J56 consisted of front discs and rear drums. However,

J56 added heavy-duty features to these components. According to Chevrolet records,

a mere 205 examples were sold that year. However, since it was only used on Z28 and

Z28 production quantities only totaled 602 for '67, that equates to slightly more

than a third of the total Z28 production.

RPO J65 was also a heavy-duty brake option, but for drum brake cars. It consisted

of both front and rear drums with special metallic shoes.

It was also a relatively rare option, ending up on only 1,217 Camaros.

RPO J56 (disc/drum)

The Z28 was a model developed by Chevrolet to make the Camaro eligible for

road racing activity in the recently formed Trans-Am series, run by the

Sports Car Club of America (SCCA). The Camaro would be competing with other

similar pony cars from rival manufacturers on road courses that exacted high

demands from suspension, drivetrain, and braking components. Since the Camaro

was a brand new model in 1967, it was vital to GM that a car capable of holding

its own against stiff competition was available to interested purchasers.

Remember, Ford fully backed its racing teams back then and GM did not, at least

not monetarily. A brake package that went beyond the abilities of the production

J50/J52 combination was deemed necessary. This is where the J56 package comes in.

The Hugh Heishman-owned '67 Z28 with driver Johnny Moore.

This road racer is exactly the type of car that the J56 brake package was designed for.

|

RPO J56 had been (and continued to be) a heavy-duty performance brake option

on Corvettes prior to the introduction of the Camaro in 1967. When the new Z28

model became available at the very end of December 1966, a Camaro-specific J56

brake package was made available for it as well. However, because the Corvette

used 4-wheel disc brakes on all models, the Camaro J56 package was different than

the Corvette J56. It combined the features from the Corvette discs with components

from proven heavy-duty drum systems.

J56 Front Discs

The J56 package used the standard Camaro 11-inch disc brake calipers but added

Pyroceram heat insulators on each of the four pistons. Under hard braking conditions, the

ceramic insulators provided an effective heat barrier between the pad and the

brake fluid. Thus, they reduced the likelihood of brake fluid boiling, which

was a crippler of braking performance. These insulators had been proven on the

Corvette racing program the year before and the technology was easily transferred

over to the Camaro.

An original, unrestored J56 front brake caliper for a

'67 Z28 (front). Pyroceram heat insulators were attached to each brake piston with

a Phillips head screw countersunk into the center. Compare to the standard J52 piston

(rear).

|

|

The above photo shows an exploded view of a J56 brake caliper.

The large spring slips over a boss on the back side of the brake piston. The seal (in front) goes on after the

piston has been installed.

|

|

The difference between a J56 (left) and a standard J52

(right) disc brake caliper are these special pistons with black ceramic heat

insulators. The heat insulators were essential for success on road race courses

and road racing was the reason for the existence of the Z28 in the Camaro lineup.

|

|

A comparison of the standard '65-66 Corvette brake

piston (left) versus the 67 J56 piston. The J56 piston has a much thicker black heat

insulator. The piston and caliper were also redesigned in 1967 to eliminate the

center piston guide. The stock 67-68 Camaro brake piston was all metal, with no

insulator.

|

|

Metallic brake pads were not provided for the front disc

calipers on J56-equipped Camaros. Chevrolet wording for the J56 option was as

follows: "Heavy Duty Front Discs With Metallic Lining Drum Rear". No service

replacement metallic disc brake pads were ever cataloged in Chevrolet parts

books (except for Corvettes), whereas the metallic rear drum brake

shoes were readily available for all models via service replacement. The way

the Camaro J56 option was specifically worded, along with the fact that Corvette

11.75-inch diameter metallic pads were cataloged while Camaro 11-inch diameter

metallic pads were not, is supporting evidence that Camaro metallic front pads

were never factory issue. As an added note, on a Z28's window sticker,

J56 is simply noted as "Heavy Duty Brake" - the word "metallic" is conspicuously

absent.

Page 2 from the Z28 introduction letter, dated December 9, 1966.

It tentatively shows J56 as a mandatory option, which turned out not to be the case. What

should be noted is that the J56 package was available for the Z28 from its inception.

This was important, because many of the first Z28s went directly to road racers who were

trying to get their cars prepared for the Trans-Am road races that began in early February.

|

In speaking with former Z28 road racers that campaigned cars during the '67

Trans-Am season, it has been discovered that an upgrade to the J56 disc/drum

brake package was made available that year. Specially modified Camaro calipers

were produced for use with the stock 11-inch rotors and were machined to accept

the HD Corvette metallic brake pads (p/n 5468882). [Note: These special Corvette

pads absolutely will not fit into stock Camaro or Corvette calipers unless the

calipers are machined to accept them.]

These Corvette brake pads used two cotter pins for retention rather than

the large single pin in the middle. They also had stiffer backing plates that served

to reduce the vibrations feeding back into the pistons and causing air leaks into

the brake system. These specially machined Camaro calipers were available through the

parts department as part numbers 5468886 and 5468887.

Interestingly, these 886 and 887 calipers are listed under the

"Special Service Parts" heading of the 1968 Z/28 brochure. Chevy also made a

blueprint available to race teams who wanted to machine their own Camaro

calipers to accept the Corvette metallic pads.

Talk about rare, here's an original J56 racing caliper. The photo illustrates

the use of two cotter pins to retain the flanged, metallic brake pads sourced from the Corvette parts bin.

The pads in the photo happen to be Raybestos replacements but they are identical in every way

to the Corvette pieces made by Delco-Moraine.

|

|

NOS Delco-Moraine metallic brake pads for J56

Corvettes and also J56 Camaro (when the front calipers are machined to fit).

The backing plate is Inconel, which is resistant to warping/distortion at

extremely high temperatures.

|

|

1967 Z28 J56 caliper shown with the GM-supplied drawing detailing

how to modify calipers to accept the Corvette J56 brake pads for road racing competition.

|

This photo shows the outer half of a front disc brake caliper (casting number 5455533).

The area circled in red shows the day of the calendar year (Julian date) when the part was cast.

Brake calipers only indicate the day they were cast, not the year.

In this particular case, it was cast on the 37th day of the year.

|

|

With the same caliper flipped around 180 degrees, we now see what the inner half

of the front disc brake caliper looks like (casting number 5455530).

Again, the area circled in red indicates the location of the casting date - the 89th day for this half.

These are a matched pair of castings from a one-owner Z28 built in July of 1967.

|

|

J56 Rear Drums

For the rear drum brakes, metallic linings from heavy-duty drum brakes were used.

The axle assemblies (which included brake drums and brake hardware) for metallic brakes

were unique and thus had unique

2-letter application codes. (Both the J56 and J65 options used the same

axles). On the metallic brake shoes, the lining was bonded on, whereas on normal

production brake shoes the lining was riveted on. This has been found to be

standard Chevrolet practice with metallic brake shoes.

The size remained constant between Camaro metallic and non-metallic rear

brake shoes, 9-1/2" x 2".

Rear brake drum removed from the passenger side of a J56-equipped 67 Z28.

[Note: The top-right light blue spring has been replaced and should be light green]

|

|

Close up view of the segmented GM metallic brake shoe, as installed.

|

|

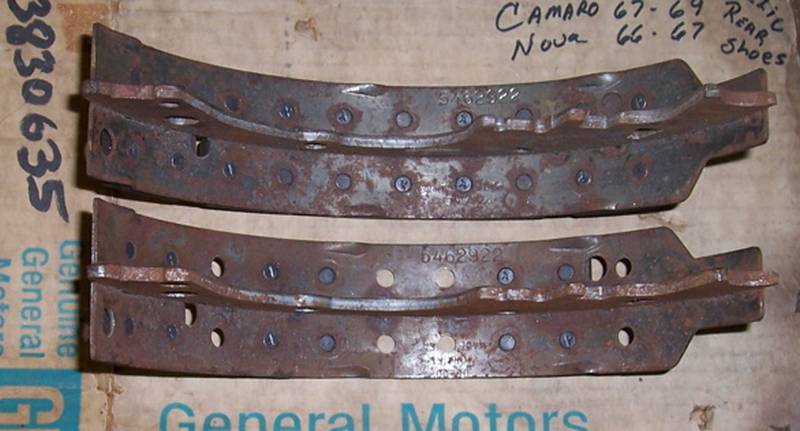

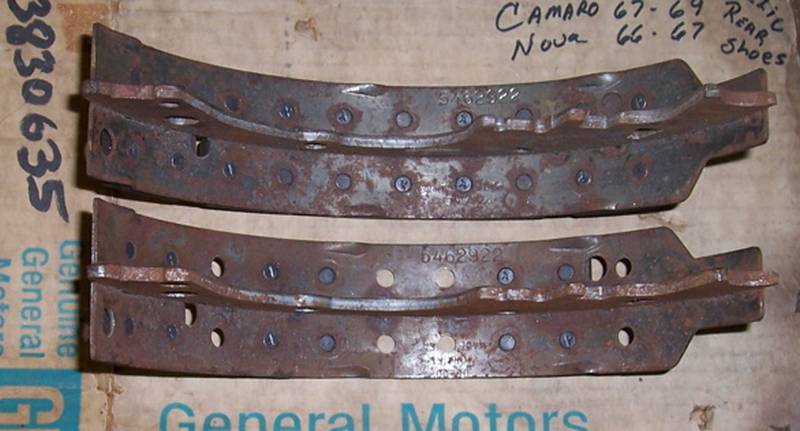

Backside of the 9-1/2" x 2" metallic rear brake shoes. A part number of 5462922

is stamped into the backside. What almost appear to be round rivet heads are actually a bit of

the brake lining that fits down in the small holes to help keep the bonded-on brake

lining material in place and also more precisely locate the individual segments.

|

Besides the metallic brake shoes, the brake shoe springs and brake drums

were unique as well. The metallic brake shoe springs are different because

they are designed to handle the higher temperatures associated with hard

brake use. [Future research hopes to determine if these springs have larger

diameter wire and/or more windings than their stock counterparts]

The metallic brake drums carried the same casting number as the normal

production part but they are not the same and are listed as a

different part number in the parts book. This was due to the fact that the

friction surface inside a metallic brake drum was ground to a finer (smoother)

surface finish than a standard production brake drum. The Chevrolet Chassis

Service Manual specifies it as a 20 micro-inch finish (a standard brake drum

finish would be 80 micro-inches or less). The purpose of this finer surface

finish was to help the metallic shoe have an easier time seating or

"bedding-in" to the drum.

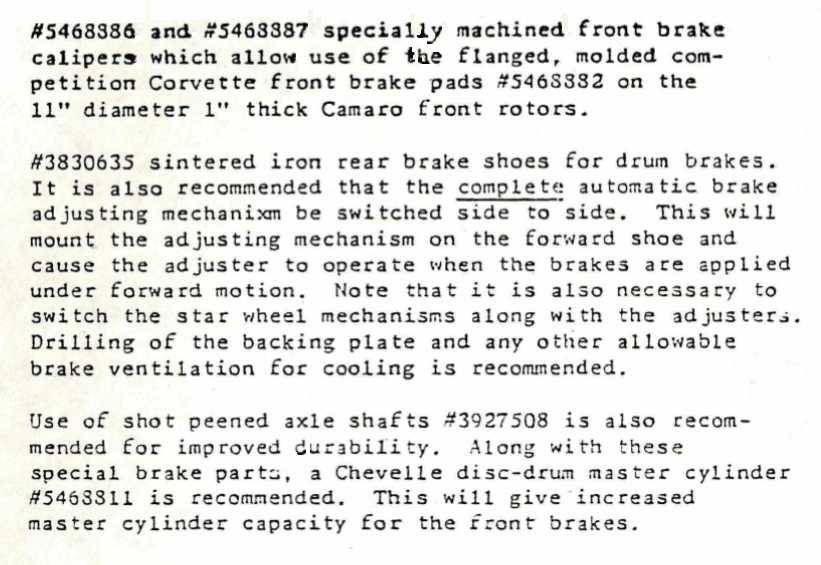

Chevrolet had been experimenting with metallic drum brake components for

10 years prior to the Camaro's introduction. Thus by that time, they were

pretty highly developed. What was new to Chevrolet was figuring out how

to mix in front disc brake calipers with drum brakes on the rear. The

challenge was having the brake modulation be predictable, plus optimizing

the overall braking effectiveness. This was not only a challenge that

needed to be solved for production cars, but it was a challenge for

people who were going to race the cars as well. The components for the

disc/drum system that led to successive wins at the end of the '67 Trans-Am

season are shown below.

Part of the Camaro Chassis Preparation sheets provided

to racers by GM.

|

|

Here is a photo of Mark Donohue's '67 Z28 road racer.

Besides using the J56 metallic brake linings inside the rear drums,

racers like Mark often drilled the drums and backing plates to help dissipate the built

up heat that caused braking performance to suffer.

|

|

A Word About Brake Drums

|

All brake drums were (and still are) a composite design; the web is steel and the outer

diameter is cast iron. The drums are centrifugally-cast in rotating molds.

The stamped steel web is inserted in the mold first, then molten

iron is poured into the rotating mold to form the cast portion of the drum.

On Corvette drum brakes ('63-'64), the web on standard and J65 drums is .110" thick,

and on the all-out J56 system, the web is .130" thick, usually with an "X" stamped in it

for identification. All research indicates that the '67 Camaro J56 and J65 rear brake drums

were identical to the standard production drum (including the same web thickness) and only

differed by virtue of the finer surface finish inside.

|

RPO J65 (drum/drum)

RPO J65 had been a heavy-duty drum brake option on all Chevrolet models

prior to the Camaro coming out in 1967. The J65 brake option was available

on all SS Camaros for the entire model year of 1967. It was available for

that one model year only and was discontinued for 1968. J65 was available

with or without J50 power assist. Essentially, the

J65 option provided more braking performance over the standard drum/drum

package for those people who did not want to pay the extra money for the

J52 discs or who were untrusting of the relatively new (to GM) disc brake

package. You have to remember this was a different era. This was why things

such as 3-speed manual transmissions on the column were still available -

to accommodate the desires of (typically) older drivers who were more

comfortable with the technology of the cars they learned to drive in.

According to Chevrolet sales literature, J65 metallic brakes were supposedly

only available on SS cars. However, CRG research has found the J65 option

on some L30/M20 (327 4bbl, 4-speed) models, including one with GM of Canada

documentation, and we believe the J65 brakes were a legitimate option for them as well.

With the front brake drum removed, you can see that the J65 front brake shoes are very

similar to the rear shoes described in the J56 section, however they are 1/2" wider, measuring 9-1/2" x 2-1/2".

|

|

Backside view of a J65 front brake shoe showing

the attachment detail and a part number of 5462921.

|

|

Front brake drum used on all drum-equipped Camaros.

The presence of a mold number (W-16X in this case, top of drum) and casting number

(3841198, bottom of pic) is the same with either standard drum brakes or J65 brakes.

|

|

The finned front brake drum

(casting number 3853549) that replaced the J65 package in 1968. It was

standard for all SS and L30/M20 cars that year.

|

|

For 1968, the J65 metallic brake package was discontinued and all SS and

L30/M20 models received finned front brake drums as a standard part of

their drum brake package. Not only did the fins aid heat dissipation,

they also acted to strengthen the drum against heat distortion. All

remaining Camaro models (L6 cars and 327's except L30/M20) with drum brakes

soldiered on with non-finned brake drums on all four corners.

All '67-'69 Camaros used the 3841177 rear brake drum casting and this was never

a finned unit. The only unique part used was the 3841177 drums installed

on the '67 J56 and J65-equipped Camaros that had a finer inner surface finish.

1967 Drum Brake Components

Spring, Brake Shoe Pull Back

3855378 Primary - Front & Rear - 4.25" long [with J65]

5462970 Primary - Front & Rear - 4.25" long [w/o J65]

3855379 Secondary - Front & Rear - 3" long [with J65]

5462958 Secondary - Front & Rear - 3" long [w/o J65]

Spring, Brake Shoe Automatic Adjusting Lever

5462097 Return - Front & Rear [with J65]

5461984 Return - Front & Rear [w/o J65]

3824720 Override - Front & Rear [with J65]

5462264 Override - Front & Rear [w/o J65]

Brake Shoes, Metallic

3845291 Fronts, J56 - set of 4

3830635 Rears, J56 - set of 4

Drum, Front Brake

3845282 [with J65] casting # 3841198 (w/finer surface finish)

3845258 [w/o J65] casting # 3841198

Drum, Rear Brake

3841188 [with J56/J65] casting # 3841177 (w/finer surface finish)

3841176 [w/o J65] casting # 3841177

|

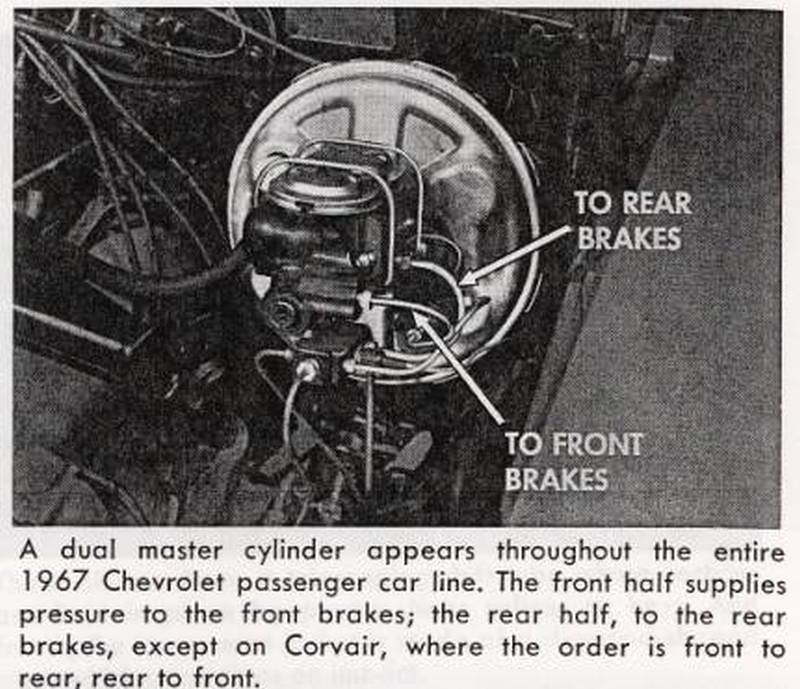

Master Cylinders and Rear Brake Line Valves

Complete information about master cylinders and

brake boosters, including the application codes, is located on the Chassis

information page, but here is basic information.

All first-generation (1967-1969) Camaros used Delco Moraine master

cylinders. The casting number was on the side of the disc brake master

cylinder and for model years 1967 and 1968 this number was 5460346.

All '67-'69 drum brake cars used the 5452310 casting except manual drum

J65 cars, which used the 5461862 casting. It is very easy to visually tell

the difference between a factory disc brake and drum brake master

cylinder. The disc brake master cylinders are wider looking and use

two bail clips to hold the cap down. The master cylinder for a drum

brake car has a narrower body and uses a single bail.

Date codes on master cylinders are not always present.

If one is present, it will be on the driver's side and will be a 1, 2,

or 3-digit number representing the day of the year. No year would be indicated.

The application code for the master cylinder was stamped on a small semi-circular pad on

the front of the casting. The master cylinders for the power-assisted J56 and J65 brake

packages were the same as regular production parts. The manual J65 master cylinder, with

it's unique casting, also had a unique application code (AU).

Manual J65 master cylinder is shown above.

The J65 casting number is 5461862 and is on the bottom right side.

The application code (AU) is by the yellow paint spot on the front of the

master cylinder.

|

|

Chevrolet used the 5460346 master cylinder all

power disc brake cars. The photo shows the wider disc brake master cylinder

with two bail clips on the cap.

|

|

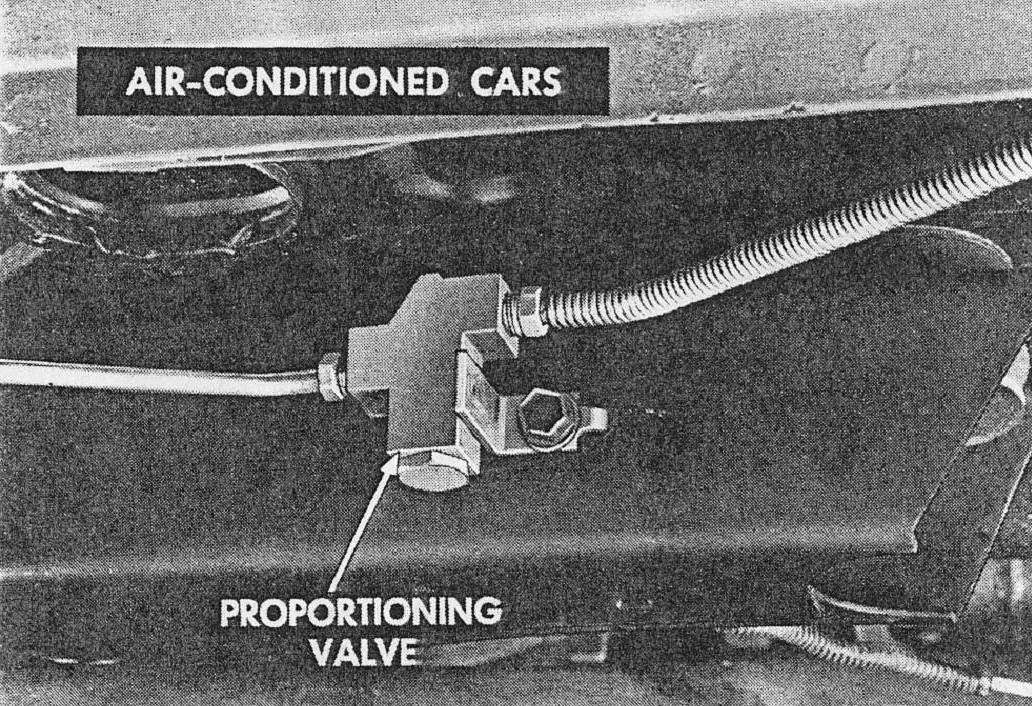

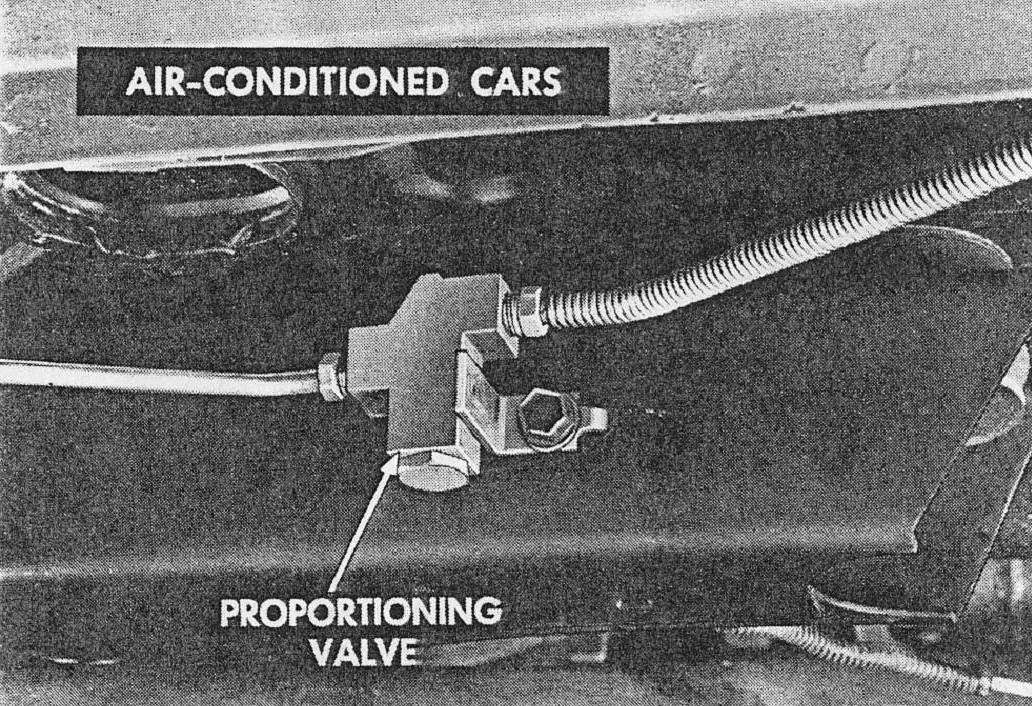

GM documentation doesn't fully correlate with actual observed usage

of the rear brake line valve.

Essentially, what has been observed on J56-equipped Z28s is that

the Norwood cars (except early builds through March) used the rear brake

pressure regulator valve and the Los Angeles (Van Nuys) cars did not.

For J65-equipped cars, the usage has the same pattern - the

Norwood cars used the regulator valve and the Los Angeles cars did not.

Exactly why the two factories did this two different ways will

probably never be known. The GM photo with caption

below implies the valve is only used on air-conditioned cars but that

is simplistic and only partially true.

Rear brake line valve is mounted

on the subframe under the driver's door.

|

Replacement Metallic Brake Shoes

Service Replacement Brake Shoes

Pardon the pun, but the metallic brake shoes "wear like iron".

Additionally, the front brakes do most of the braking. Hence, original

rear metallic brakes been found still in place on many original J56 and J65 cars.

Replacement metallic brake shoes for the front and rear were available through the

Chevrolet parts department and obviously the rigors of racing would

have worn out original shoes far faster than those used on street cars.

Replacement shoes were sold as a set of four to a box, with two being

needed for each rear wheel. The front metallic shoes were P/N 3845291 and the rear

metallic shoes were P/N 3830635. Again, the fronts and rear were very similar, with the fronts being 1/2" wider.

Set of four rear metallic brake shoes that make

up P/N 3830635. The two with less lining material pads are the leading or

primary shoes (which face toward the front of the car) and the two with

more lining material are the trailing or secondary shoes.

|

|

Rear metallic brake shoes oriented as if they were installed left side of the car

(The front of the car would be to the reader's right).

|

|

Leading metallic brake shoes show original ink stamps stating "Delco 101 F.F.".

Trailing shoe ink stamps state "Delco 102 EE". The periods are not always used after the letters EE or FF.

|

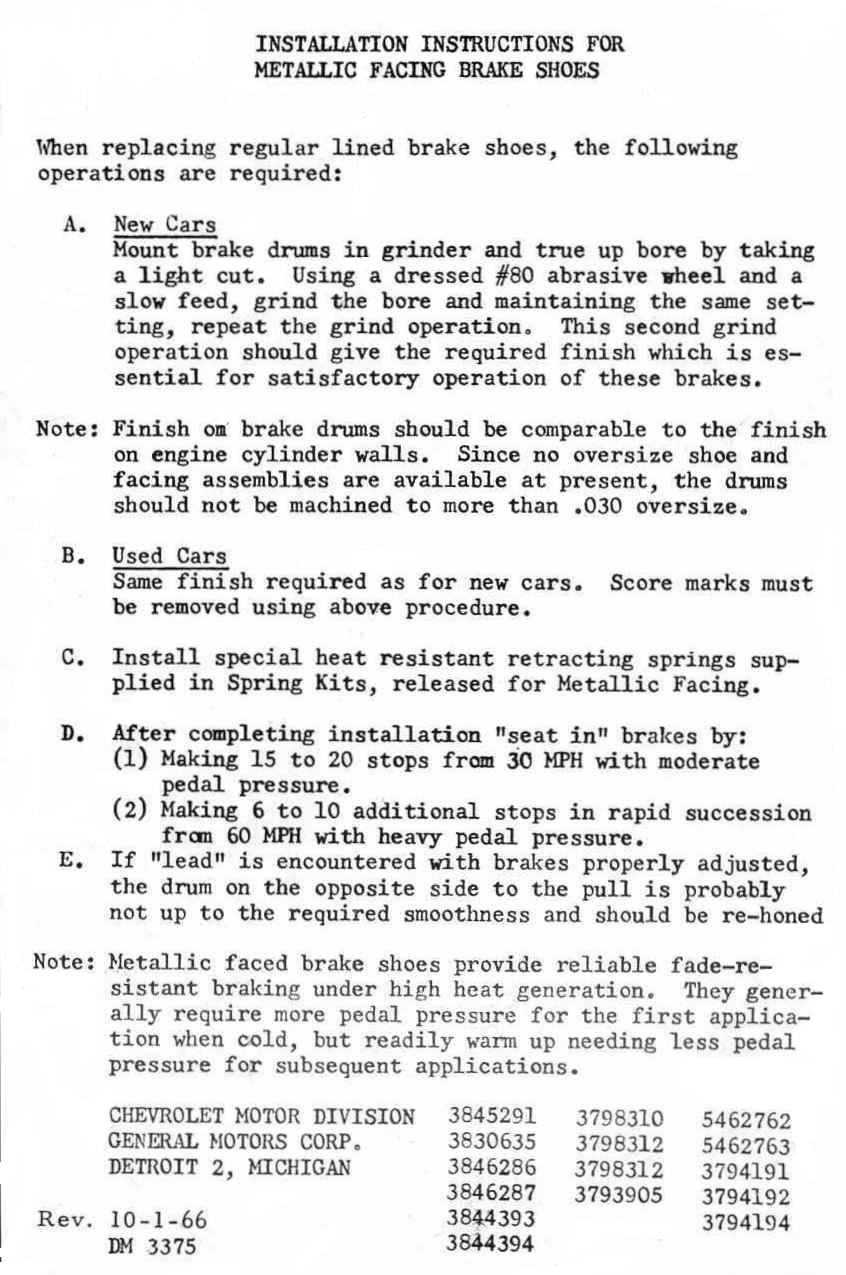

The instruction sheet that comes in the box of Chevrolet replacement metallic brake shoes.

|

|

The washers that come in the box of Chevrolet metallic

brake shoes. The yellow instruction sheet describes their intended use. The washers

are .625" O.D, .250" I.D. and .030" thick.

|

|

Aftermarket Metallic Brake Shoes

As might be expected, there were some aftermarket companies that also

made metallic brakes including shoes very similar to the Chevrolet

offerings. Two such companies were Lakewood and Velvetouch. [Note:

Velvetouch brakes were marketed and sold by Lakewood Industries prior

to 1973 before becoming two separate entities.] Other companies

included the Raybestos and Grey Rock brands. Although the Chevrolet

pieces are quite good, some people just gravitate toward aftermarket

products if they have a choice. No doubt many owners replaced GM brake

parts with others available through their neighborhood parts store or

speed shop. While this is getting us a little off course in terms of

the intent of the article, I felt it might be of interest to some

readers to see what else was available and what some original GM

components may have been replaced with.

The Lakewood version of Camaro brake shoes

is segmented but not the same way as the Chevrolet parts. These are NOS

and are no longer available.

|

|

|

Summary

The '67 Camaro heavy-duty brake options are a subject that has not

previously received much press in the Camaro hobby. The JL-8 4-wheel disc brake

package of '68 and '69 seems to get all the glory but it is part of a larger

story, the next chapter if you will, of the groundwork laid down by the metallic

brake packages for the '67 model year. It is

hoped that this report has given the reader a better understanding

that these were well thought out and developed packages and the J56

brakes in particular had a legitimate, albeit short, racing pedigree.

They truly were a very special part of the Camaro performance legacy.

Acknowledgements

The author would like to acknowledge and thank the following people

who contributed information to this article: Robert Lodewyk, Allan

Mason, Troy Criscillis, Fred Hucke, John Hinckley, Hugh Heishman,

Gary Morgan, Bob Morton, Ted Muneno, Ron Shaw, Pete Sande, Phil Bate,

and Larry Christensen.

You readers can help serve to improve any future revisions of this

report. We would appreciate verification of individual brake parts,

master cylinders, body broadcast codes, chassis broadcast codes or

any other items that you feel may provide pertinent information on

the subject. Digital photos of these same items are greatly

appreciated as well as they serve to expand our knowledge of what

is and is not correct for these cars.