|

| C R G | CRG Reports | Exterior | Engine | 1967 Model ID |

| Numbers Decode | General Info | Interior | Transmission | 1968 Model ID |

| Drivetrain Decode | Options | Underhood | Chassis | 1969 Model ID |

©1998-2023, Camaro Research Group

Edited by Rich Fields and Kurt Sonen

Version: Sunday, 19-Mar-2023 16:04:38 EDT

It is a reliable, smooth transmission and capable of very respectable performance. The Powerglide in "built" form was the preferred drag-race transmission for quite a few years, and is still popular for drag racing.

In 68-69, there was a low cost version of the Powerglide, RPO MB1, that was marketed as the Torque-Drive. The Torque-Drive had a manual shift valve body and was approximately $100 cheaper than the Powerglide. It was only available with 6-cylinder engines.

The test fleet included full-size Chevrolets, Chevelles, Novas, and Camaros. The vehicles were initially assigned as Chevrolet company cars, for use at both at the assembly plants and at the division level. Afterwards, they were sold as used company cars.

The cars were built with several different engine models and over a range of build dates. For the Camaro test vehicles, the TH350 was available with the base 327 (210 hp), the L30 (327/275hp), and the L48 (350/295hp). All three engines have been observed in 68 Camaros, though the L30 appears to be the most common. The engines will have unique engine suffix codes of MI, EN, and MF. The cars were built at both LOS and NOR assembly plants, but most were built at Norwood. Production was from May through the end of 68 production in July.

When the TH350 was released in 1969, it outsold the Powerglide 78,849 units to 66,423. Like the Powerglide, it was only available with 6-cylinder and small block V8 cars (Z28 excepted), as the Camaro big-block engines had too much torque for the TH350. The transmission model number comes from the nominal torque rating, 350 lb-ft of torque.

The base manual transmission for non-high-performance models and 67-8 SS350's was the Saginaw 3-speed, M15. If no transmission option was selected, this was the transmission installed. It was column shifted unless a console or RPO M11 floor shift was selected. An exception to this was SS350's, which required the HD 3-speed to get a floor shift.

For 1967-68 SS models, the heavy-duty 3-speed manual transmission, made by Borg-Warner,

was available as RPO M13 . For SS350 models, M13 was optional (but was required

if you wanted a floor shift). For SS396 models, M13 was a required option

if another transmission was not ordered.

In 1969, the heavy-duty 3-speed was supplied by Muncie and changed to RPO MC1.

It was only available as a floor shift and was available on

LM1 and SS models. For the LM1, it

was a required option if another transmission was not ordered. For 69 SS models,

the HD 3-speed trans was included in the SS package.

Maincase Gear Ratios

RPO Years Casting 1st 2nd 3rd Comments

---------------------------------------- ----------

Saginaw

M15 67 3858986 2.85 1.68 1.00 L6 engine

67 3858986 2.54 1.50 1.00 V8 engine

68-69 3925647 2.85 1.68 1.00 L6 engine

68-69 3925647 2.54 1.50 1.00 V8 engine

Borg-Warner

M13 67-68 T16-1 2.41 1.57* 1.00 * noted as

1.59 in 68

Muncie

MC1 69 3911982 2.42 1.58 1.00 both castings

3911940 used in 69

|

For lower performance applications (L6, 307, 327, and L65 350), the Saginaw 4-speed was utilized. It used a cast iron case. For higher performance applications (LM1 350, SS350, big blocks, and Z28) the Muncie 4-speed was used. It used an aluminum case and different gear ratios from the Saginaw 4-speed.

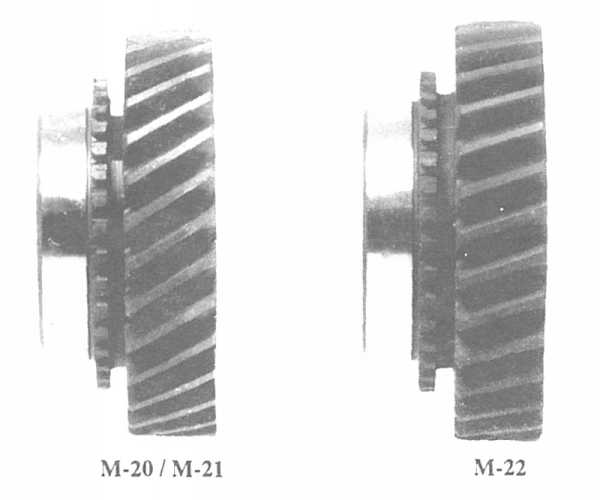

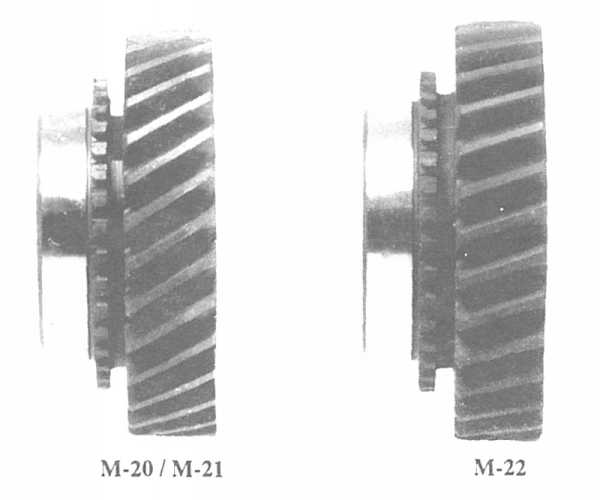

The wide-ratio Muncie 4-speed transmission was marketed under RPO M20. The close-ratio version of the Muncie 4-speed was RPO M21 and the heavy-duty close-ratio 4-speed was RPO M22.

The wide-ratio Muncie M20 was available with any of the high-performance

engines, except the L78 and Z28 in 67 only came with the M21. The M20 was

the only 4-speed available with the SS350 and the SS396/325 hp (L35) engines.

The close-ratio M21 was available only with the

SS396/350 hp (L34) engine and the solid lifter engines (Z28, L78, and COPO).

The heavy-duty M22 was limited to just the solid-lifter engines, starting

in Camaros in 1968. The Muncie usages are also shown on the ID tables (e.g.

the 69 ID table).

The Camaro 4-speed manual transmissions ratios for both Muncie and Saginaw, with other Muncie data, are as follows:

Maincase Gear Ratios Input Grooves Cluster Output

RPO Years Casting 1st 2nd 3rd 4th Spline (Input) Pin Spline

-----------------------------------------------------------------------

Saginaw

M20 67 3915032 3.11 2.20 1.47 1.00 L6 engine

M20 68-69 3925656 3.11 2.20 1.47 1.00 L6 engine

M20 67 3915032 2.54 1.80 1.44 1.00 V8 engine

M20 68-69 3925656 2.54 1.80 1.44 1.00 V8 engine

Muncie

M20 63-65 3851325 2.56 1.91 1.48 1.00 10 None 7/8" 27

M20 66-67 3885010 2.52 1.88 1.46 1.00 10 2 1" 27

M20 68-69 3925660# 2.52 1.88 1.46 1.00 10 2 1" 27

M20 70 3925661 2.52 1.88 1.46 1.00 10 2 1" 27

M20 71-74 3925661 2.52 1.88 1.46 1.00 26 2 1" 32

M21 63-65 3851325 2.20 1.64 1.28 1.00 10 1 7/8" 27

M21 66-67 3885010 2.20 1.64 1.28 1.00 10 1 1" 27

M21 68-69 3925660# 2.20 1.64 1.28 1.00 10 1 1" 27

M21 70 3925661 2.20 1.64 1.28 1.00 10 1 1" 27

M21 71-74 3925661 2.20 1.64 1.28 1.00 26 1 1" 32

M22 65 removed 2.20 1.64 1.28 1.00 10 None 1" 27

M22 66-67 3885010 2.20 1.64 1.28 1.00 10 None 1" 27

M22 68-69 3925660# 2.20 1.64 1.28 1.00 10 None 1" 27

M22 70* 3925661 2.20 1.64 1.28 1.00 10 None 1" 27*

M22 71-74 3925661 2.20 1.64 1.28 1.00 26 None 1" 32

# Some late-production 69 Camaros came with Muncie 3925661 maincases.

* The 1970 M22 used in 454 Chevelles used the 1971-74 output shaft.

|

The transmission code is normally located on the passenger side of the transmission, arranged vertically just in front of the tailhousing joint. See the transmission decoding information for pictures and more information.

To distinguish between Muncie types, if the Muncie was built after 21-Oct-1968, the transmission code contains one of three letters at the end of the build code:

A = 2.52:1 Wide Ratio (M20)

B = 2.20:1 Close Ratio (M21)

C = 2.20:1 HD Close Ratio (M22), aka "Rockcrusher"

If the input shaft is visible, the number of circumferential grooves on the input shaft will also generally indicate the Muncie type. Be careful, as 1963-65 M20 Muncies are like later M22s in that they have no input shaft grooves. However, the early M20 has only a 7/8-inch diameter cluster pin, while the M22 has a 1-inch pin. Service replacement input shafts also will have no grooves.

To distinguish an early (pre-suffix) M22 from the other Muncies when the transmission is on a car, note that all M22s had the lower, forward, passenger-side maincase boss drilled and tapped for a magnetic drain plug. This wasn't done (by the factory) for M20/M21 until 1970. While this boss could be drilled for a plug on a M20 after it left the factory - if the boss is undrilled, then the case definitely was not part of a M22.

The M22 gears have a shallower mesh angle to reduce thrust load and heat. If the gearbox cover is removed, the difference in the angle between the M22 gears and the gear angle used in the other Muncies is discernable. Note in the photo below that on the M20/M21 the bottom of the next tooth starts below the top of the preceding tooth (i.e., they overlap), whereas on the M22 the angle is such that the teeth actually have a small gap between the top of one tooth and the bottom of the next.

|

The shallower mesh angle of the M22 causes a "whine" noise in 1st, 2nd, and 3rd gears and the sound is the reason for the popular nickname for this transmission, the "Rockcrusher." The lower angle increases the load carrying capacity of the gears at the expense of the increased noise. The reason for absence of the noise in 4th gear is that 4th is a direct output from the input (1:1 ratio), and there are no significant gears involved.

For additional details on other transmission component casting numbers, component casting dates, and internal transmission details, see Colvin's Chevrolet By The Numbers series, listed in the CRG References.

All 1967-69 Camaro 3-speed transmissions transmissions used Muncie shifters. 1967-68 Camaro 4-speed transmissions (Saginaw transmissions as well as Muncie) also used Muncie shifters.

The stock Muncie shifter was mounted by a bracket to the transmission crossmember and further supported by a longitudinal stabilizer. This caused problems in performance applications due to the transmission twisting under load and binding the shifter levers - causing many a missed shift. The stock Muncie 4-speed shifter was often replaced by the aftermarket Hurst Competition-Plus shifter. The Hurst shifter mounts directly to the transmission housing, instead of the transmission crossmember, which eliminates the shifter binding issue. The 67-68 Hurst aftermarket bracket used U-bolt around the tailhousing.

The Muncie shifter in 1967 was generally stamped "MUNCIE" on the handle, though

some shifters have unmarked handles.

The Muncie shifter on the Saginaw was not stamped, while the Muncie shifter

on the Muncie transmission was generally stamped "MUNCIE". There are known

exceptions to this rule though.

1969 Camaro 4-speed transmissions (Saginaw and Muncie transmissions) used a factory installed Hurst shifter. The Saginaw transmission required different shift rods than the Muncie and the Muncie small block rods were different than the big block rods. The factory Hurst shifter was similar to the over-the-counter Hurst Competition-Plus model, but differed in the following ways:

|

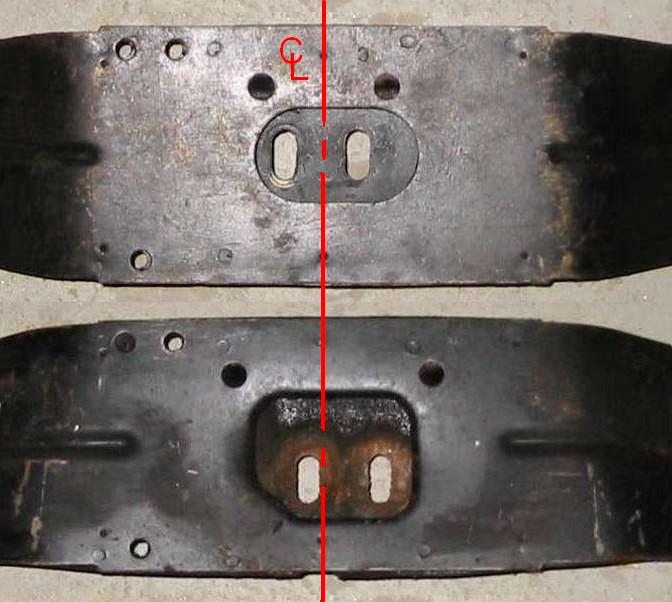

The BB manual transmission crossmember looks similar to the SB version, but the BB crossmember opening is squared-off with a beveled corner whereas the SB opening is oval (see picture). The transmission mounting slots for the BB manual trans crossmember are also in a different location than the SB version. The slots are offset about 1/2 inch towards the passenger side and about 3/4 inch forward.

Both crossmembers are mounted such that the two shifter mounting holes (top left holes in the picture) are rearward.

The crossmember used by the 67-68 Firebird looks very similar to the BB crossmember. It has a squared-off opening with a beveled corner like the the BB crossmember, but the trans mounting slots are centered side-to-side (see sketch).

The 69 Firebird used a one-piece crossmember. It was basically just the upper part of a 67-68 Firebird crossmember (i.e. it is missing the bottom part with the opening).

The Camaro BB TH400 crossmember is different from the other crossmembers in that it is formed from tubing. The Camaro TH400 crossmember has the mounting plate welded about 1/2 inch off-center. The Firebird TH400 crossmember is also made from tubing and looks very similar, but the mounting plate is centered.

Transmission Crossmembers Offset ---------------------------------------- 67-69 L6 and SB none 67-69 BB manual trans 1/2" 67-69 BB TH400 1/2" 67-69 Firebird none 67-69 Firebird TH400 none

|

|

|

Quoting from the Chevrolet Dealer Service Information Bulletin, 69-I-1, dated 19 Sept, 1968:

The following system will be used to identify service engine and transmission assemblies* including replacement parts. Manufacturing plants will number each assembly as it is produced. The first letter will designate the GM division which produced the engine. |

Most service parts were produced specifically for service. Production engines and transmissions were generally not used as service parts.

|

|