Production Options

©1998-2024 Camaro Research Group

Edited by Kurt Sonen

Version: Monday, 28-Oct-2024 12:26:04 EDT

- Options List - Downloadable RPO Spreadsheet (PDF)

- Option Identification

- Wheel and Wheel Cover Options

- Valve Stems & Valve Stem Extensions

- 1967 Camaro Front Shoulder Harnesses

- Features of the Custom and Special Interiors

More information on seat belts and seat belt options appears in the

-

CRG Research Report:

Camaro Seatbelts

Options List - RPO Spreadsheet

This is the complete list of all Camaro options, including the description,

cost, and number produced.

This PDF documents all the Regular Production

Options (RPO's) for all three first generation years. It

includes the official production totals and prices for each option,

a description of the option, and an indication of some of the major

dependencies between the options (what other features are required

for an option and also what is not allowed with an option).

Notes and Limitations

- The source for the RPO information is various GM documentation.

The source for the production data is also ultimately GM,

but it was published by Len Williamson and he has graciously allowed

us to use it. The detailed reference is contained on our CRG reference page as well as

contained within the spreadsheet.

- This file is in PDF format, so you must have a working version of

Adobe Acrobat Reader (or other PDF compatible

reader/viewer) to read this file. Acrobat Reader is a free program.

- This file is the copyright property of the Camaro Research Group,

and is subject to the same restrictions as

any other data on our web site. Do not download this file unless you can

comply with these restrictions.

Click (or Shift-Click) to download the

CRG RPO spreadsheet file in PDF format, version 12-Jul-2021.

Option Identification

This section is to help identify which options were originally equipped on a car from the factory.

1967 Camaros will have many of these options indicated on the cowl tag.

Firewall without AC

|

|

|

Firewall with AC

|

|

Air Conditioning (RPO C60): The most unique and identifying

feature of an AC car is the firewall. To mount the AC evaporator on the

firewall required a hole in the firewall of different size and shape from

a non-AC car. The hole for AC is the same for all models, including L6, SB, and BB.

The AC wiring passed through a large hole directly beneath

the right-side window washer squirter and the air diverter valve was installed

in the cowl plenum. The addition of air conditioning caused

a myriad of other changes such the center air vent in the dash, different heater

controls, and different kickpanels. The Assembly Manual shows the details of the

changes to the wiring, interior, engine, etc.

On 67 cars, the trim tag will be stamped 2E to indicate AC.

Console (D55): Approximately half of all 67-69 Camaros received a console

from the factory. The console was optional on all models except for cars with

bench seats. The console was retained to the floor with a front mounting bracket and

special collapsing rivet nuts (a.k.a. rivnuts) in the floor. The mounting bracket

holes are in front of the shifter. The

rearmost rivnut should always

be in the floor even if the floor was cut up for different shifters.

The console in 67 will be noted on the trim tag as 2G.

Spoilers (D80): The spoiler option was not available in 1967 on any Camaro.

It became available as an option on all cars (except those with a rear

antenna) in 68-69. It was not mandatory

on any car, except for the 69 pace car replicas and later 69 Z's. The

narrower 68 spoiler was used on the 69 Camaro up to January - March of 69,

when the wider 69 spoiler was phased in.

One of the torsion bars on an original spoiler equipped car will be of

larger diameter to compensate for the weight of the spoiler. The front center

of the 69 subframe will have a drilled hole to mount the center brace of the

front spoiler.

Transmissions: All manual transmission cars received the clutch pedal,

smaller brake pedal, and the clutch bellcrank (z-bar) for the clutch fork.

The front subframe of a manual transmission car would have the clutch bellcrank

bracket holes with tapped threads; the subframe of an automatic car would still

have the holes but without threads.

All 4-speeds and floor shift 3-speeds have a hole in the transmission tunnel

for the shifter. The style used mainly in 67 & 68 was a clean-cut rectangular

shaped hole which had a reinforcing ring welded to the underside of the

tunnel around the shifter opening. The reinforcement ring was used on the

following applications: all 1967 floor shift models (AT and MT), 1968 all MT

floor shift, 1968's with the TH400 M11 floor shift (w/o console), and 1969 models

with 3-speed manual w/o console. The hole cutout for 1969 models equipped with a 4-speed

was smaller and more "oval shaped" than the other design. It was also rough cut

with a torch and did not use the reinforcement ring welded to the bottom of the tunnel.

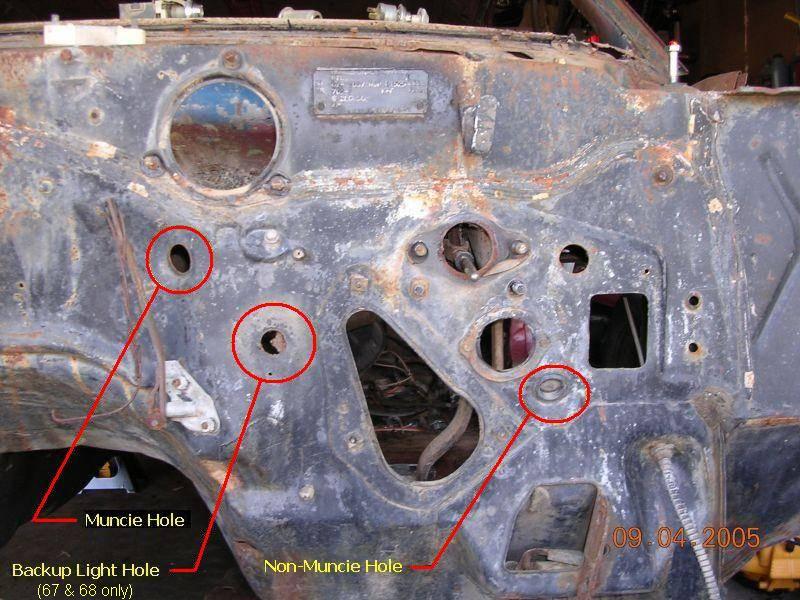

4-speed cars with higher performance engines received the Muncie transmission.

The speedometer drive was on the passenger side of the transmission.

The speedometer cable for Muncie-equipped cars exits the firewall on the

right side of the steering column, above and behind the driver's side valve

cover just above the throttle rod pivot, and it uses three clips to secure it

to the firewall and tunnel. All other transmissions (including the M20 Saginaw)

had the speedo cable exit on the left side of the steering column.

Speedometer hole locations

|

|

|

67-68 shifter reinforcement plate

|

|

|

68-69 tunnel with auto shifter

|

|

Automatic transmissions: The default shifter was a column

shift unit. If a console was ordered, a floor shift would then be used

(except with a 68 SS396, where RPO M11 was available which provided a

floor shift without a console).

The hole in the tunnel for the 67 auto floor shifter was the same as the 67

manual shifter. The 68-69 shifter mounted to the floor with several bolts

and there was a hole for the shifter cable between the shifter and the

front mounting bracket (see pic).

1969 dual exhaust doubler plate

|

Dual exhaust (NF2, N10, N62): Dual exhaust was an option for any V8 and was

standard on all SS, COPO, and Z's. On 68 coupes, rivnuts were used on the driver's

side frame rail (just behind the rear tire) to attach the dual exhaust hanger.

On 69 coupes, a reinforcement (doubler) plate was added to the rear frame rail

in the same area.

Gauges (U16 or U17): The U17 gauge option was an option on any V8

car and required the ordering of a console. It included the tach, clock,

fuel, oil, amp, and temperature gauges. The underdash wiring harness will have extra wiring

going to the console wiring connector for the gauges and a different

connector for the tachometer. There was a hole drilled in the firewall just

behind the distributor for the oil line. In 69, the cluster will have

a different cutout for the tach than for the standard fuel gauge.

Later 69 V8 cars were available with the U16 Tachometer which consisted of

just a tachometer and a center mounted fuel gauge. A console was not required.

Later 69 Z28's were the only model that required a tachometer (via either U16 or U17).

Radio: Radios were a common option (more than 85% of first gens had

one). A bracket was used to hold the rear of the radio

in place. AM radios used a telescoping antenna and AM/FM used a solid mast

antenna. The holes for the antenna cables were on all cars. Cars with rear

antennae or no radio received a plug in this hole. The multiplex and stereo

tape speakers were mounted in the kick panels. The rear speaker wiring was

routed down the right side of the car, under the steel wiring covers.

Rally Sport (Z22) was an appearance only option that was

available on all models in 67-69. It consists of concealed headlights with

a different grille and back-up lights under the rear bumper and included the Z21

style trim package. 67 & 68 RS cars used a different front valance panel with

the front parking lamps/turn signals mounted in the valance instead of the

grille. 69 RS's included the RPO CE1 headlight washer system

with the Rally Sport option. On 67 cars, RS will be noted on the trim tag with a 3L code.

The 67-68 RS fenders have an extra mounting bracket welded to the fender

for the RS headlight assemblies. The 69 RS fenders have different mounting tabs

than standard fenders.

In 67, the headlights were electric. 67's have the associated wiring for the

headlight motors and relays. 68-9 were vacuum operated.

68-9's have a 1" hole in the firewall (just outboard of the master cylinder)

for the vacuum lines to the special headlight switch. The 68-69's have

extra holes stamped into the inner fender for mounting the actuators and

bellcrank mechanisms. 69 RS cars (and those with CE1) also had a special solenoid

valve on the wiper motor to divert washer fluid to the headlight washers.

1969 fender mounts (RS on bottom)

|

|

|

68 & 69 RS vacuum line hole

|

|

|

1969 RS headlight washer valve

|

|

All RS's have stamped holes in the rear panel for the backup lights.

There are holes in the trunk for the wiring to the backup lights -

67 and 68 holes are in the same location under the taillights,

whereas 69 are outboard of the trunk bracket. The rear wiring harness has longer

leads for the backup lights and the taillights are all red.

In 69, the RS taillight housing does not have a hole for the backup bulb.

1968 RS innner fender

|

|

|

1969 RS innner fender

|

|

|

1967 & 68 RS trunk wiring

|

|

1969 RS trunk wiring

|

|

|

1968 RS back-up light stamped hole

|

|

|

1969 RS back-up light stamped hole

|

|

67's will have holes in the doors for mounting the RS lower trim. 68's

will have have the holes in the doors and also mounting holes in the

fenders and quarters for the RS trim.

Holes for RS trim in 1968 door

|

|

|

Holes for RS trim in 1968 quarter

|

|

Cowl hood (ZL2): The cowl hood was an option on SS and Z28 models in

1969 and was included on all COPO's and Pace Cars. It was introduced midyear 69.

#1 ZL1, built 12E at Norwood is one of the first Camaros to have a factory ZL2 hood.

A late December LOS-built Z28 with ZL2 has also been documented.

The ZL2 option included a solenoid and flapper in the hood. The wiring for the solenoid was

routed through a special hole in firewall

above the fuseblock. Only 10,026 cars received cowl hoods in 69 and about half of

those went to COPO's and Pace Cars, meaning there were only 5,000 Z28's and SS's

(out of about 20,000 Z28's and 30,000 non-Pacer SS's) that received the cowl hood.

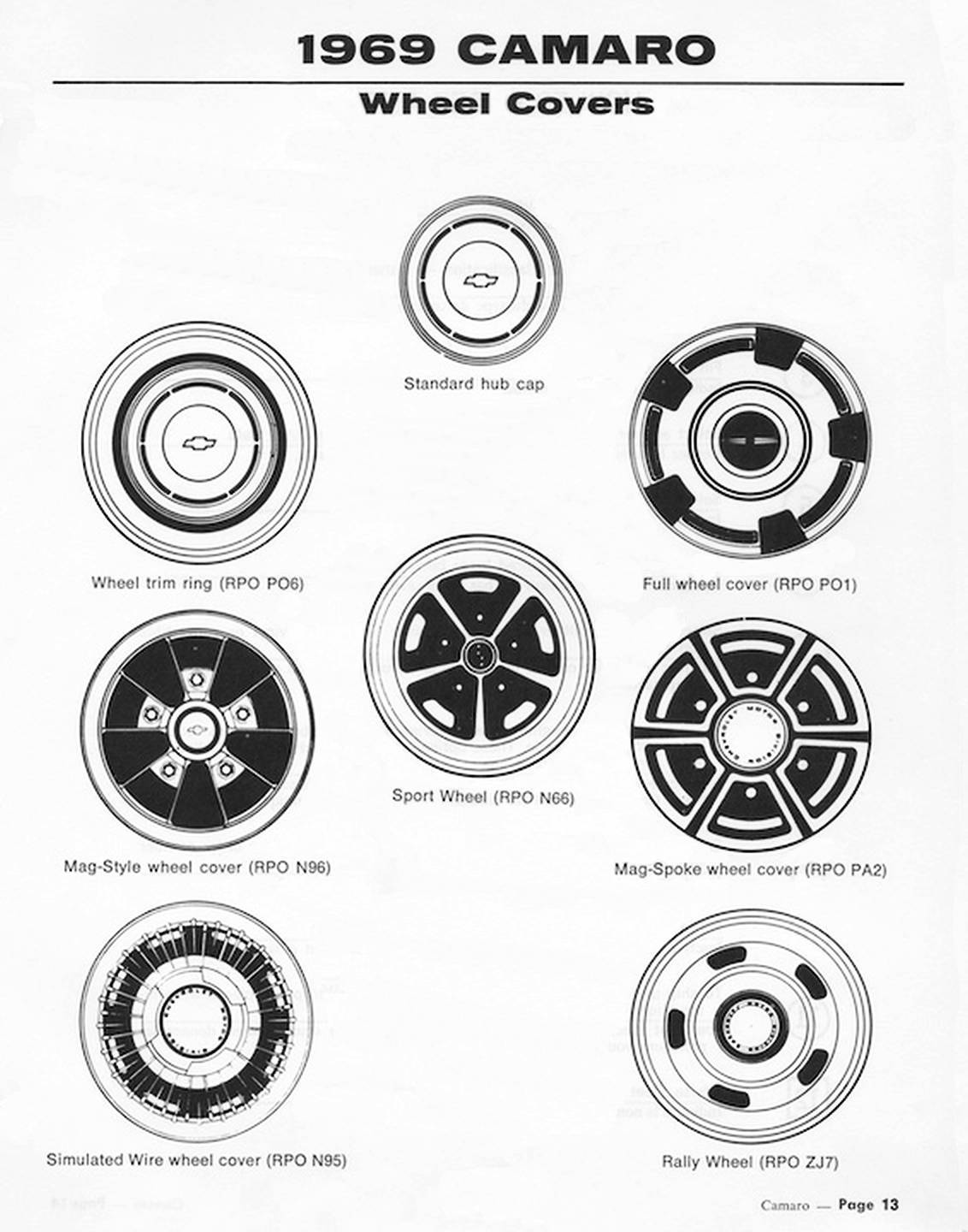

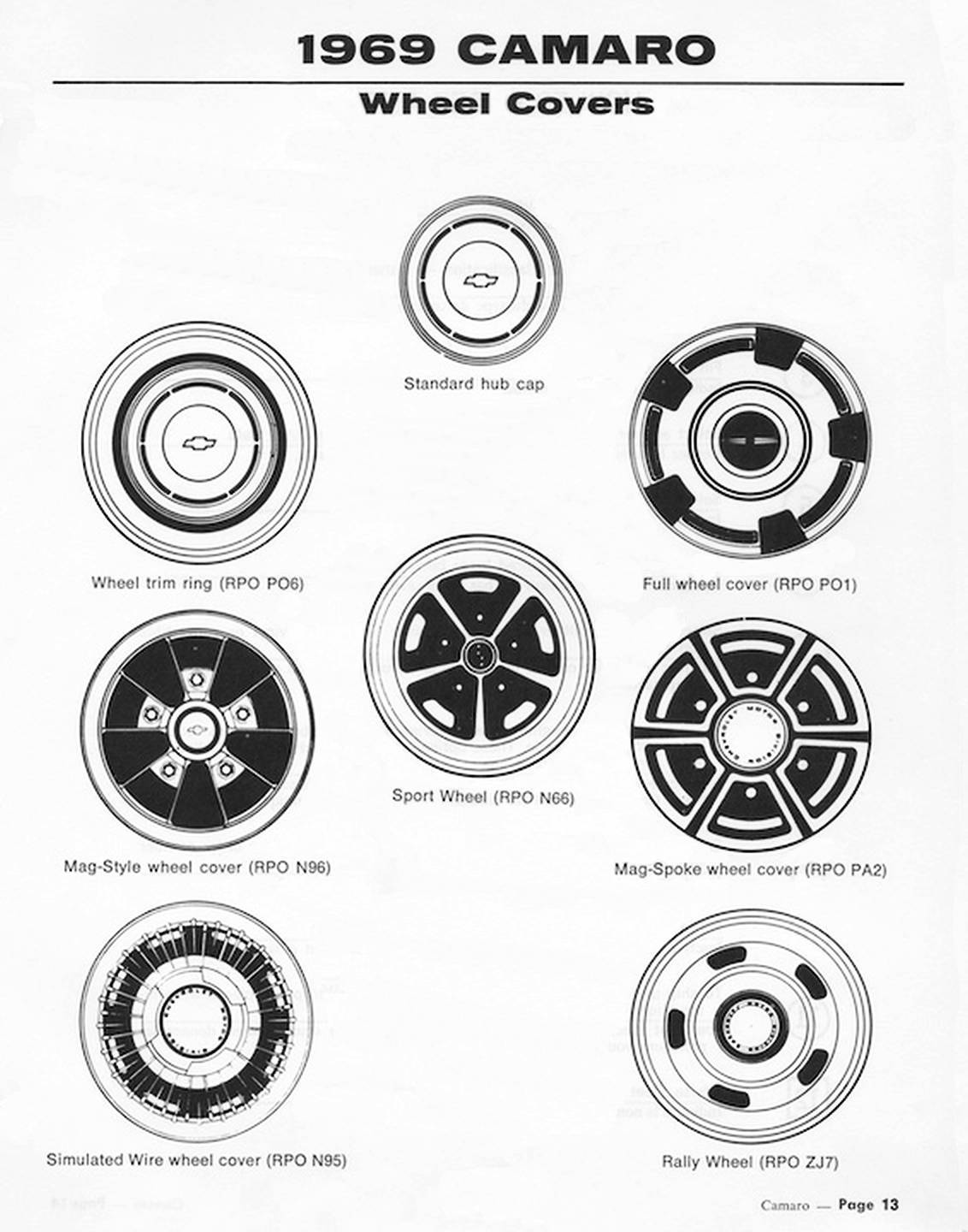

Wheel and Wheel Cover Options

(Specs on wheels are found here: Wheels.)

The 'dogdish' hubcap was the base hubcap if no other wheel option was ordered.

It was attached to the standard steel wheel painted in body color enamel.

The 67 version of the hubcap differed from the 68/69 version. In 69,

there was a P06 trim ring option that was installed around the base

hubcap (covering a significant amount of the body colored wheel).

| 67 base hubcap |

68 & 69 base hubcap |

69 base hubcap with P06 trim ring |

|

|

|

There were several optional wheel covers. These covers would be installed over

the black-painted steel wheel. The P01 hubcap was a low-cost ($21.10) full wheel

cover that was very popular - it came on over half of all 67-69 Camaros.

There was a unique SS-only P01 version that only came on SS cars ordered with P01.

This wheel cover was used starting April 67 on 67 cars and during the 68 model year.

Early 67 SS's and all 69 SS's with P01 used the standard P01 cover.

The N96 magnesium-style wheel cover was available in 67-69. Another mag-style

wheel cover (PA2) was introduced in 68 and was also available in 69.

There was a wire wheel cover option, P02, offered in 1967. It changed RPO

numbers to N95 for 68 and 69. In 1967 and 1968, the wire wheel cover had a bowtie design

on the center. In 69, that was changed to “Chevrolet Motor Division” on the center.

All of these mag-style and wire wheel covers cost $73.75 and

a screwdriver (part #3798116 in 67) was included in the trunk to aid in cover removal as

the tire iron will bend the covers.

| 67 P01 wheel cover |

68 & 69 P01 wheel cover |

Late 67 & 68 SS P01 cover |

|

|

|

| N96 mag-style cover |

PA2 mag-style cover |

P02/N95 wire wheel cover |

|

|

|

There were also three wheel options.

- In 67, the base 14x5 wheel could be

upgraded to the wider 14x6 wheel (included with SS models) via RPO P12. 14x6 wheels

became standard in 68.

- The rally wheel was included with disc brakes in 67.

In 68 and 69, it was RPO ZJ7 and was available on any vehicle. The 68-69

version had a taller center cap than the 67 version. The rally

wheel was included in the Z28 package in all three years.

- The N66 wheel, aka the SS wheel, had very limited production in the beginning of

the 69 model year before being cancelled effective 1/8/69.

| 67 rally wheel |

68 & 69 rally wheel |

69 N66 wheel |

69 wheel covers |

|

|

|

|

Valve Stems and Valve Stem Extensions

by Bernard McDonald

9417745 extension

by Dill

|

|

Set of 9422212 extensions

|

|

The standard valve stem assembly used all three years years on all wheels was a snap-in

type rubber TR-413 with tire valve stem cap. The tire valve stem assembly with cap was 1-1/2”

in length overall, 1-1/4” effective length (i.e., length of stem from the wheel).

Both “DILL 627” and “SCHRADER” valve stem caps have been observed on original cars.

A valve stem extension was required for all full-wheel cover options, but not for

partial-wheel hubcaps. If required, valve stem extensions were placed in the glovebox

at the assembly plant.

Valve Stem Extensions

| Year |

Wheel Cover RPO |

GM Part No. |

Valve Stem Extension length |

OEM Part No. |

| 1967 |

N96 P02 |

9417730 |

3/8" effective |

tbd |

| 1968 |

N95 N96 P01 |

9417730 |

3/8" effective |

tbd |

| 9417745 * |

1/2" effective |

Dill 685-P |

| 1968 |

PA2 |

9422212 |

1" effective |

Dill 687-P |

| 9417466 * |

1 1/4" effective |

Dill 688-P |

| 1969 |

N95 P01 |

9417730 |

3/8"effective |

tbd |

| 1969 |

N96 |

9417745 |

1/2" effective |

Dill 685-P |

| 1969 |

P02 |

9422212 |

1" effective |

Dill 687-P |

| 1969 |

PA2 |

9417466 |

1 1/4" effective |

Dill 688-P |

|

* GM documentation was updated 2/12/68. |

1967 Camaro Front Shoulder Harnesses

By Jon Mello, CRG, with assistance from Blake Allan

[Note: More information on seat belts and seat belt options appears

in the Camaro Seatbelts Report.]

First-generation Camaro shoulder harnesses began as optional

equipment, separate from the standard lap belts. The

shoulder harness options, RPO AS1 for standard belts and

RPO A85 for deluxe belts, were not very common. Total

production for the 1967 model year was less than 1400 sets.

1967 Convertible Shoulder Harness

(Click on image to expand)

|

|

|

|

The shoulder harnesses are well known to '68 and '69 Camaro owners because they

became standard equipment on coupes as required by Federal Law beginning 1 January,

1968. However, the '67 version is a unique animal compared with these later harnesses.

'68-'69 Camaro owners are accustomed to finding two sets of belt buckles between their

front seat and the drive shaft tunnel. However, the '67 shoulder harness set-up has

only one buckle in this location; the second belt has a metal "male" clip.

The shoulder belt with the buckle is attached to the roof.

In the case of a convertible, the shoulder belt with the

buckle is anchored in the retracting top well.

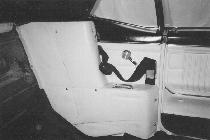

Coupe Shoulder Harnesses

Unlike the 1968-69 shoulder belts, which tuck behind the

coat hook and metal guide above the front passengers' heads,

the '67 harness hangs straight down from its roof mount and

the buckle slips into a plastic receiver clip, as shown below.

The receiver clip is mounted via two sheet-metal screws to

the side/rear upholstered panel. Camaros with the deluxe

interior or fold-down rear seat had the shoulder belt clip

mounted on the front edge of the rear seat arm rest.

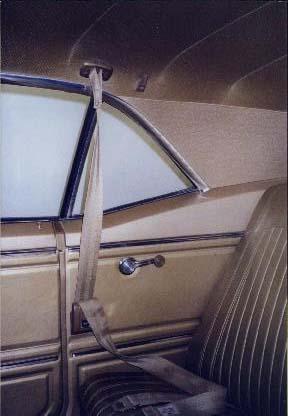

1967 Coupe Shoulder Harness Attachment

|

|

|

Shoulder Harness Receiver Clip

(no rear arm-rest)

|

|

|

Shoulder Harness Receiver Clip

on rear armrest

|

|

Some cars which have the rear seat arm rests still have the receiver clips on

the rear upholstered panel. At this point, one can only assume that specific

instructions for mounting the clips were either never given out or simply were not

strictly followed. We are trying to research further to see

if it may have been done differently at different times of

the year or if it is due to two different factories but,

because of the rarity of the option, examples have been a

little hard to find. If you own a '67 Camaro with the

shoulder belt option, the CRG would appreciate hearing from

you. The hope is that we may someday be able to provide a

definitive answer to the two different clip mounting

positions.

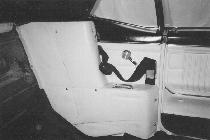

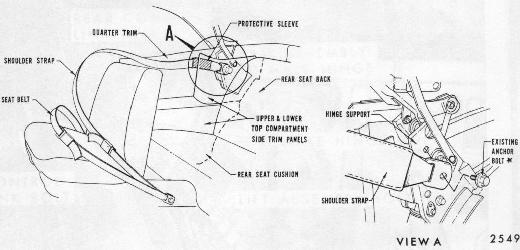

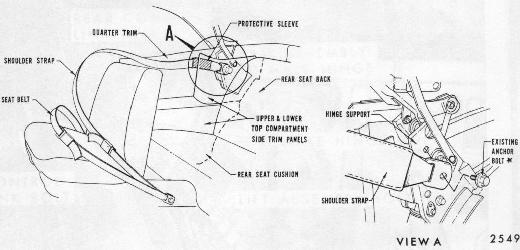

Convertible Shoulder Harnesses

By not having a fixed roof, the Camaro convertible obviously

needed a different solution to mounting the shoulder

harness. This harness was secured under one of the anchor

bolts for the top mechanism, as shown in the Fisher Body

schematic below, and the accompanying photo.

1967 Camaro Convertible Shoulder Harness Attach

|

The shoulder belt then slips out of the top well between the

rear quarter upholstered panel and the top compartment side

trim panel. A protective sleeve is supposed to minimize wear

on the belt where it slips through.

Convertible Shoulder Belt Anchor Point

|

|

|

Driver's side w/o seat

|

|

|

Driver's side - assembled

|

|

The Design Problems

These rare shoulder harness options lasted only one year in this

configuration and for good reason -- they were poorly conceived

and had issues in daily use.

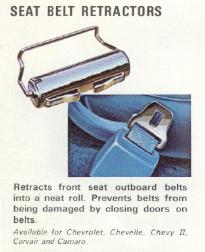

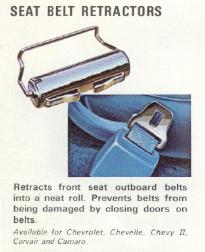

Accessory Retractor

|

When not in use, there was no place for the excess length of the belt

to go but to dangle on the seat or the floor. One solution for dealing with the

excess belt length was to install a bail type seat belt retractor.

These items were not a factory installed part but were listed in

Chevrolet dealer accessory pamphlets. The belt retractors look to be nice

solution at first glimpse but, in actual practice, they are cheaply

built and function poorly.

With the seat belts fastened and cinched across the body, the

extra belt length did not fall neatly across your lap but

dangled over next to your arm, as shown in a photo above.

Also, when not in use and with the windows down, the buckles

would fly out of their receiver clips and crash around the

rear seat area due to wind buffeting.

The 67 design was changed to the more familiar style for model year

1968. However, shoulder belts remained an option on coupes until 1 Jan 1968,

when the new Federal Motor Vehicle Safety Standards came into effect.

If you have a Camaro with optional shoulder harnesses, you

can take pride in having one of the more rare and (for '67

especially) unusual Camaro options available.