|

| C R G | CRG Reports | Exterior | Engine | 1967 Model ID |

| Numbers Decode | General Info | Interior | Transmission | 1968 Model ID |

| Drivetrain Decode | Options | Underhood | Chassis | 1969 Model ID |

©1998-2025, Camaro Research Group

Edited by Kurt Sonen

Version: Monday, 15-Dec-2025 23:58:17 EST

|

| Spring Part Number | Overall Length, inch | Number of Coils | Coil Diameter, inch | Wire Diameter, inch | Coil Twist | Hook Opening** | Preload Displacement, inch | |

|---|---|---|---|---|---|---|---|---|

| For SS Hoods | 3848272 | 9-3/8 | 28 | 1.420 | 0.225 | Right-Hand | -75 degrees | 0.075 |

| For Flat Hoods and ZL2 Cowl Induction |

3877203 | 8-3/4 | 26 | 1.475 | 0.195 | Right-Hand | +105 degrees | 0.640 |

|

* dimensions are nominal ** relative to open hook at other end where a + angle is in a clockwise direction and a - angle is in a counterclockwise direction. | ||||||||

The base spring, though less stiff, is significantly preloaded even at the maximum opening position (shortest extension). However, the SS spring is almost completely unloaded in the fully opened position. This can be seen from the "pre-load displacement" value in the table above.

The ends of both springs are hooked, with the hook of each end oriented at near right angles relative to the other end. However, there is a difference between the two springs even in this detail. (Reference the comparative photo and the schematic.) When using one open hook end as the angle reference axis, the hook at the opposite end of the non-SS spring is oriented at about +105 degrees from it. In contrast, the opposite end of the SS spring is oriented at about -75 degrees - or a full 180 degrees from that of the non-SS spring. In other words, with one end of both springs oriented in the same direction, the plane of the hooks at the other end is the same, but the open end of the two hooks are in opposite directions.

|

|

For 67, 68, and most of 69, all the batteries used top post terminals. For the latter part of 69 production, the standard batteries were modified (they stayed the same size and rating) to side post terminals (called "sealed terminals" in Delco terminology). Here is the 5/31/69 bulletin announcing the batteries with 'side-mounted terminals'.

For LOS cars, the change to side post batteries occurred about the 05A week (cowl tag date). For NOR cars, it appears the change to the Y77 side post battery occurred in late April, while the R79 side post battery was used starting in early- to mid-May. (See the Battery Usage section for application information.)

| Y77 Battery - side post |

|

| R79 Battery - side post |

|

| R69 HD Battery - RPO T60 |

|

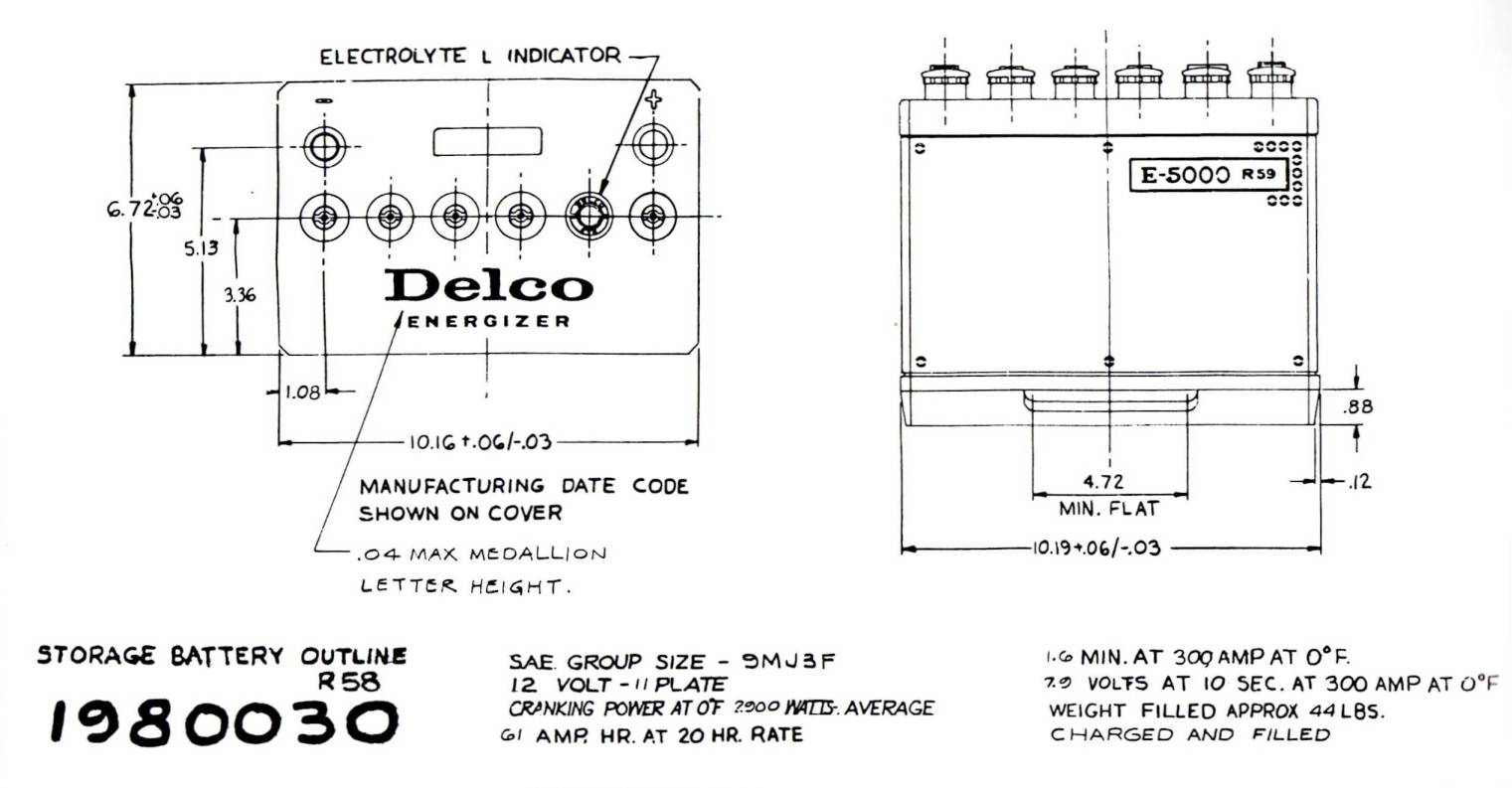

| R58/R59 Battery Drawing |

|

The part number of these new batteries was a combination of the color of the series it was in and the last two digits of the former three digit Delco part number. For example, the R69 was in the Red series and was formerly Delco part number 569.

| Year Used | Delco Model # |

AABM Group # | Post | Ahr rating | Cranking Power at 0°F (watts) | Size (l x w x h) |

Weight |

|---|---|---|---|---|---|---|---|

| 67, 68, early 69 | Y55 | 22F | top | 45 Ahr | 2300 | 9 1/2 x 6 13/16 x 8 1/4 |

34 lb |

| late 69 | Y77 | 72 | side | 45 Ahr | 2300 | 9 1/16 x 6 15/16 x 8 1/4 |

34 lb |

| 67, 68, early 69 | R59 | 24 | top | 61 Ahr | 2900 | 10 1/4 x 6 13/16 x 8 1/4 |

44 lb |

| late 69 | R79 | 74 | side | 61 Ahr | 2900 | 10 1/4 x 6 15/16 x 8 25/32 |

44 lb |

| 67-69 | R69 | 24T | top | 70 Ahr | 3150 | 10 1/4 x 6 13/16 x 9 1/2 |

49 lb |

| References: Delco Energizer Battery brochure, Jan 1966 Delco Battery Catalog, Mar 1970 |

|||||||

Here are some explanations of the battery codes used in the table above.

The Association of American Battery Manufacturers (AABM, now called Battery Council International (BCI)) standardized batteries into numbered Group Sizes according to maximum overall dimensions, terminal arrangement, and features that affect battery fit. The "F" suffix, e.g. 22F, originally stood for 'Ford' and indicates a reversed terminal post arrangement (see the description below of the Y55 battery). The "T" suffix, e.g. 24T, indicates a taller version, by 3/4", of the battery group size 24. This allowed for larger plates and thus more cranking power.

Late 69 L6, 302 (Z28), and 307: The standard battery became the Delco Y77 with side post terminals and the same 45-Ahr rating. The Y77 had two different size terminals, a 3/8-16 positive terminal and a 5/16-18 negative terminal, so the terminals could not be interchanged. The Y77 used standard terminal positions (positive terminal inboard), not the reversed polarity terminals like the Y55 it replaced.

67, 68, and early (pre-May) 69 327, 350, 396, and 427: The standard battery was the R59. It was a 61-Ahr rated battery with top posts and standard terminal positions (positive terminal inboard).

Late 69 350, 396, and 427: The standard battery became the Delco R79 with side post terminals and the same 61-Ahr rating. The R79 battery had two different size terminals, a 3/8-16 positive terminal (positive terminal inboard) and a 5/16-18 negative terminal, so the terminals could not be interchanged. (The R89 battery replaced the R79 in 1971 and had the same basic exterior dimensions, but the R89 had a single terminal size, 3/8-16.)

67-69 RPO T60, Heavy Duty Battery: The optional battery was Delco R69, a 70-Ahr battery with top posts and standard terminal positions (positive terminal inboard). This battery was a taller version (by 3/4 inch) of the R59, with the extra height allowing larger battery plates and hence more power. Unlike the standard batteries, it did not change to a side post configuration in late 69.

|

Horns may look similar, but are mostly unique to a vehicle application due to: the bracket (length and angle), the orientation of the bracket to the projector, and the orientation of the electrical connector to the projector. The bracket is staked to the horn so it is difficult to change the bracket or its orientation. Horns were mounted with the opening facing downward so water would drain out. The part number is on the bottom side of the horn flange - 9000 is molded into the horn and the last 3 digits of the part number are stamped next to it. The date is stamped on the opposing side of the horn flange. The date format is [year][month][week], where month is the letters A-M, e.g. 9B4 is 4th week of February, 1969.

An interesting video by Delco-Remy showing the horn manufacturing process in 1984 is available on Youtube.

On 1967 and 1968 standard headlight cars, the horns were mounted on the front of the driver's side of the radiator support. For Rally Sport cars, the horns were mounted on the hood latch support. Both years used the same parts - 9000477 was the low note horn and 9000214 was the high note horn. (The 477 horn was also used on 1964 full-size cars.)

RPO U03, tri-volume horn, was an available option in both 67 and 68 and added a 3rd horn (D-note @ 300hz). In 67, the third horn, part # 9000508, was mounted inside the front of the left fender. In 68, the part number changed to 9000268 and the horn was mounted on the hood latch support (shown in AIM page below).

|

|

|

|

|

|

In 69, the two horns were mounted to the hood latch and RPO U03 was not available. Part # 9000289 was the low note horn and 9000290 was the high note horn. Both part numbers were also used on 1970 Camaros.

|

|

|

|

|