|

| C R G | CRG Reports | Exterior | Engine | 1967 Model ID |

| Numbers Decode | General Info | Interior | Transmission | 1968 Model ID |

| Drivetrain Decode | Options | Underhood | Chassis | 1969 Model ID |

1967-69 Camaro Emission Systems

© 2005-2016, Camaro Research Group|

Reviewed by the CRG Last Edit: 18-Nov-2015 Previous Edits: 23-Jan-2015, 12-Mar-2012, 07-Sep-2008, 17-Feb-2008, 27-Oct-2005 Original Release: 25-Oct-2005 All images by the author unless otherwise noted. |

|

|

|

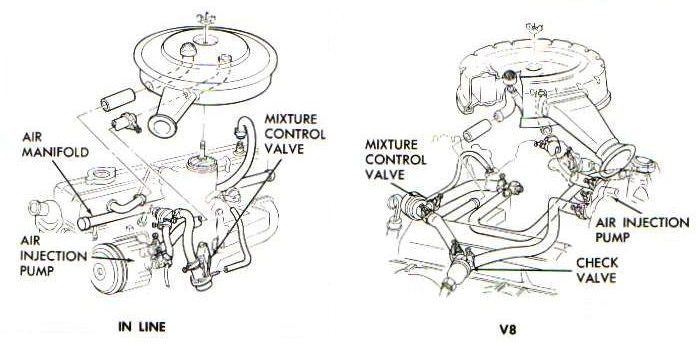

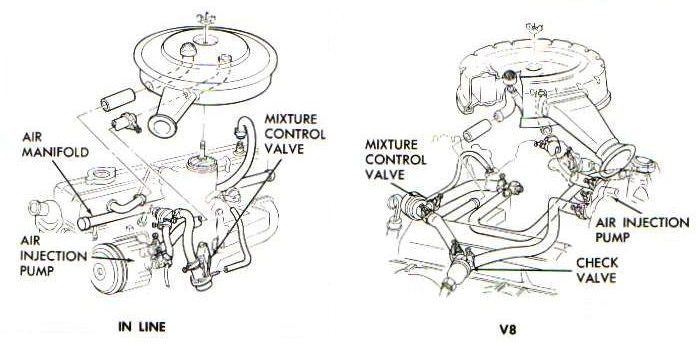

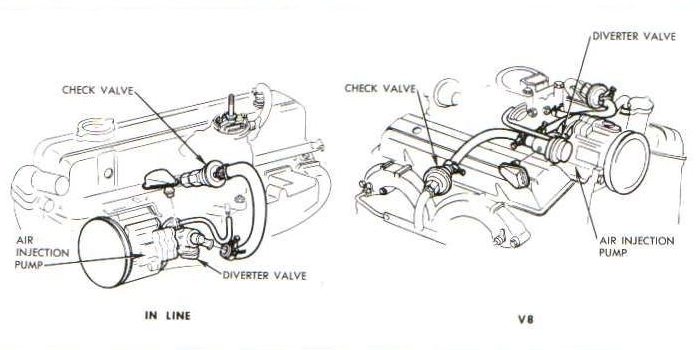

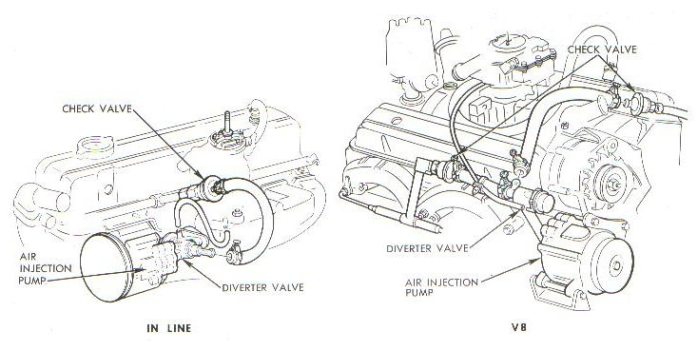

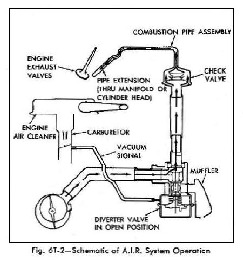

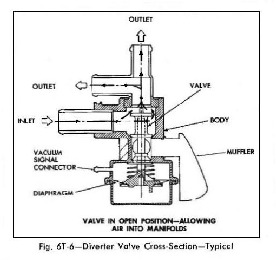

| 68-69 AIR System Diagram | Diverter Valve Diagram |

|

|

|

| 1967 | 1968 | 1969 | |||

| Engine | Part No. | Part No. | Broadcast Code |

Part No. | Broadcast Code |

| L6 | 7027093 | 7024766 | FB | 7029291 | GB |

| LF7 and 307 | 7033545 | 7024767 | FD | 7029293 | GD |

| L30 and 350 | 7033546 | 7024768 | FG | 7029295 | GF |

| Z28 | 7024765 | DH * | |||

| 396 and 427 | 7033547 | 7024764 | DG | 7029297 | GH |

| * CT on early vehicles | |||||

|

|