Finally the cam from Crane has been broken in...but it didn't happen without any problems!

The starter was the first thing that dint work as is should...one thing that happened was that someone, wasn't me though, mounted the flex plate the wrong way! Then we had to shim the starter a lot of times before we could use it with satisfaction...

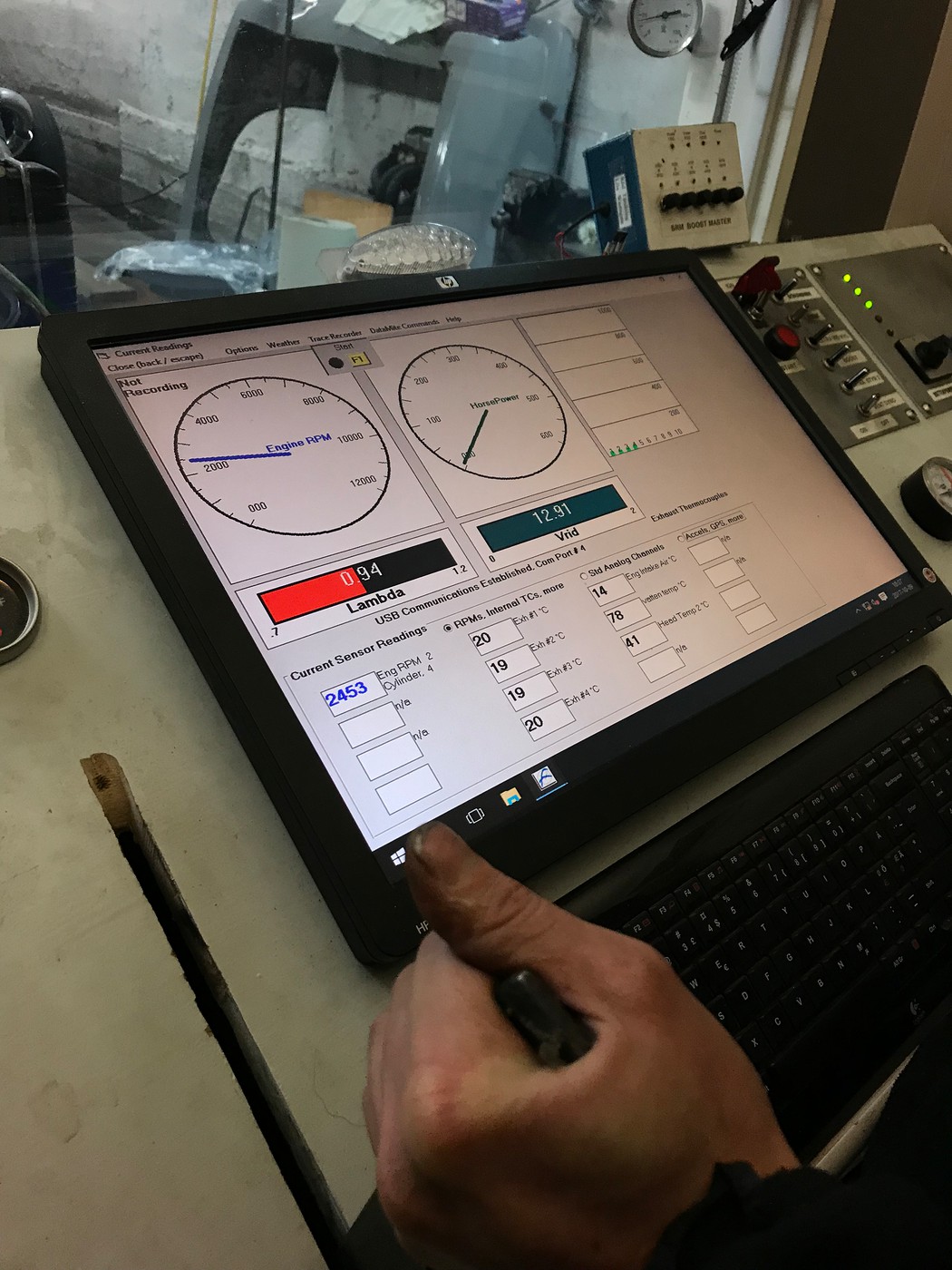

The next thing that we discovered was the internal electrical system on this home made dyno wasn't build for these type of BB Chevy engines so we almost blew it trying to start the mighty ZL-1!

The owner made a quick fix and then it was almost ok...

This dyno has been adapted for smaller Volvo and Beemer engines with turbos and other cheating parts!

When we finally got the ZL-1 to run it was just to find out that it didn't run on all eight so we just hit the emergency button! Responsible for this debacle was yours truly, who really is a newbie in engine building and therefore hadn´t adjusted the hydraulic lifters correctly and that caused the engine to NOT run on all cylinders! Do again, do right!

We then had difficulties with getting the timing correct, the strobe lamp wasn't working as it should. We tested another lamp but with same result so the next thing to look at was the cables and ignition coil. After a couple of starting attempts we realized that that the reused ACCEL coil from the old 355 finally gave up!

This ACCEL coil had been working great on my 355 so I thought it was ok to reuse it on the ZL-1 in an attempt to cut the budget but that backfired!

We also discovered some bad cables and the only good thing about this is that these kind of problems are nice to discover now while the engine is sitting in a bench instead of being mounted in the car! :roll:

The owner of the dyno had an old HEI-distributor on a shelf in deep storage so we borrowed that for further testing on the dyno and it worked ok. :|

When we finally got the engine running on all cylinders it ran very nice and smooth on idle ...you actually could do the comparison with the famous RR-engine where you could put a standing coin on top of the engine and it would not fall! Many thanks to my engine shop that did the internal balancing!

After a successful break-in of the cam we took the oil pan down for inspection of oil and particles.... nothing suspicious was found and that felt nice as well. I really appreciate the one-piece seal during this inspection!

While the cam was broken in with just the outer springs mounted, the complete set of springs now had to be in place. To get the tight spring rates and height we realized we had to order new retainers from USA and of course that delayed the whole process again..

When this parts had arrived and mounted together with all the springs we had to adjust the hydraulic lifters once more..piuuh, its a lot of unexpected things to consider when building an engine!

I borrowed a very nice tool for mounting springs though, very handy!

An old and very used HEI-distributor, not mounted in pictures above, together with almost home made ignition cables and a carb from the CSB 355 that's not optimal for the ZL-1 are not the best conditions for getting a real deal dyno test of a ZL-1 but we will try to get back here with one when the engine still is on the dyno...

the hours in the bench are running away as well!